Intro

Discover 3D printables models, featuring intricate designs, STL files, and printing tutorials, with related 3D modeling software and additive manufacturing techniques.

The world of 3D printing has revolutionized the way we design, create, and interact with physical objects. At the heart of this technology are 3D printable models, which are digital files that contain the instructions for a 3D printer to create a specific object. These models have opened up a vast array of possibilities for innovation, creativity, and practical application across various industries and hobbies. Whether you're an engineer, artist, educator, or enthusiast, 3D printable models offer a unique and exciting way to bring your ideas to life.

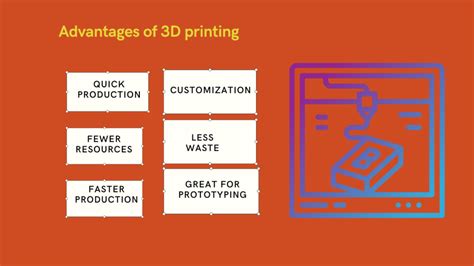

The importance of 3D printable models cannot be overstated. They enable the rapid prototyping of products, allowing for quicker testing and refinement of designs. This capability is particularly valuable in fields such as aerospace, automotive, and healthcare, where precision and functionality are paramount. Moreover, 3D printing technology, fueled by these models, has made it possible for individuals and small businesses to produce customized products that would otherwise be too expensive or complex to manufacture through traditional methods.

For hobbyists and educators, 3D printable models offer a fascinating way to explore science, technology, engineering, and mathematics (STEM) concepts in a hands-on manner. Models of historical artifacts, scientific instruments, and even entire cities can be printed and used as educational tools, making complex subjects more engaging and accessible. The community surrounding 3D printing is also remarkably vibrant, with countless online platforms and forums where designers share their models, exchange ideas, and collaborate on projects.

Introduction to 3D Printable Models

Understanding the basics of 3D printable models is essential for anyone looking to dive into the world of 3D printing. These models are typically created using computer-aided design (CAD) software or other 3D modeling tools. The design process involves crafting a digital representation of the object, taking into account the intended use, material properties, and the capabilities of the 3D printer that will be used to produce it. Once a model is designed, it is exported into a format that 3D printing software can understand, such as STL or OBJ, and then sliced into layers that the printer can execute.

Designing 3D Printable Models

The process of designing 3D printable models requires a combination of creativity, technical knowledge, and attention to detail. Designers must consider the structural integrity of the model, the type of material that will be used for printing, and how the object will be used. For instance, a model designed for functional use might require a different design approach than one intended for decorative purposes. The good news is that there are numerous software options available for designing 3D models, ranging from free, user-friendly programs like Tinkercad to more advanced, professional tools like Autodesk Inventor.Benefits of 3D Printable Models

The benefits of 3D printable models are diverse and far-reaching. One of the most significant advantages is the ability to produce customized products with complex geometries that cannot be achieved through traditional manufacturing methods. This capability has revolutionized fields such as prosthetics, where customized limbs can be designed to fit individual patients perfectly, enhancing their comfort and mobility. Additionally, 3D printing reduces material waste, as it is an additive process that builds objects layer by layer, unlike subtractive manufacturing methods that cut away material from a larger block.

Applications of 3D Printable Models

The applications of 3D printable models span a wide range of industries and hobbies. In education, these models can be used to create interactive learning tools that help students understand complex concepts in a more engaging way. In healthcare, besides prosthetics, 3D printing is used to create models of organs for surgical planning, dental implants, and even personalized medicines. The automotive and aerospace industries utilize 3D printing for rapid prototyping and the production of lightweight, complex parts that cannot be manufactured through traditional means.Working with 3D Printable Models

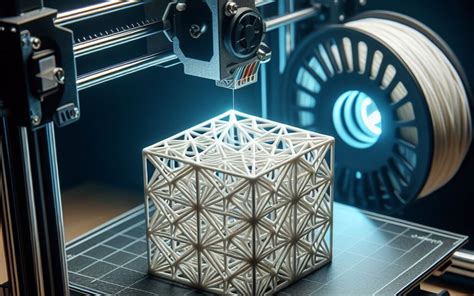

To work with 3D printable models, one needs a 3D printer, 3D modeling software, and a computer to operate these tools. The process begins with designing or downloading a 3D model, then preparing it for printing using slicing software. The model is then sent to the 3D printer, which reads the design layer by layer, depositing material according to the specifications of the model. The choice of material can vary widely, including plastics, metals, ceramics, and even food products and living cells, each offering different properties and applications.

Steps to Create 3D Printable Models

Creating a 3D printable model involves several key steps: - **Design**: Use CAD software or another 3D modeling tool to create your design. - **Export**: Export your model into a 3D printing compatible format. - **Slice**: Use slicing software to divide your model into printable layers. - **Print**: Send your sliced model to the 3D printer. - **Post-processing**: Depending on the model and material, additional steps like sanding, painting, or applying a coat may be necessary.Practical Examples and Statistical Data

Practical examples of 3D printable models can be seen in various aspects of life, from the production of custom phone cases to the creation of architectural models. Statistical data shows a significant growth in the 3D printing industry, with forecasts indicating that it will continue to expand as technology improves and costs decrease. For instance, the global 3D printing market was valued at approximately $12 billion in 2020 and is expected to reach $63 billion by 2025, growing at a CAGR of 24.3% during the forecast period.

Future of 3D Printable Models

The future of 3D printable models is promising, with advancements in technology expected to make 3D printing faster, more affordable, and capable of producing objects with greater complexity and precision. Innovations in materials science are also anticipated to play a crucial role, enabling the creation of models with unique properties such as conductivity, transparency, or the ability to change shape in response to environmental stimuli.For more information on how to get started with 3D printing, consider checking out our guide to 3D printing for beginners.

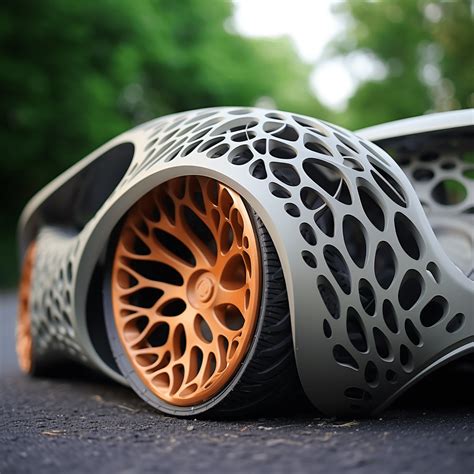

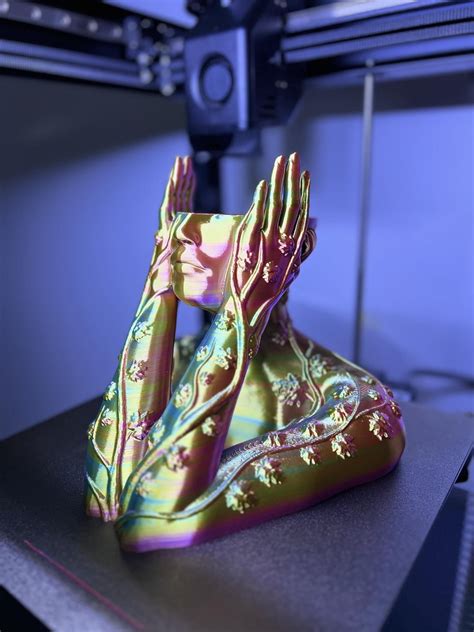

Gallery of 3D Printable Models

3D Printable Models Image Gallery

Frequently Asked Questions

What is a 3D printable model?

+A 3D printable model is a digital file that contains the instructions for a 3D printer to create a specific object.

How are 3D printable models designed?

+3D printable models are designed using computer-aided design (CAD) software or other 3D modeling tools.

What are the benefits of 3D printable models?

+The benefits include rapid prototyping, production of customized products, reduction of material waste, and the ability to create complex geometries.

As we move forward in this era of technological advancement, the role of 3D printable models will continue to evolve, offering unprecedented opportunities for innovation and creativity. Whether you're a professional looking to leverage 3D printing for commercial applications or an enthusiast exploring the hobbyist side of this technology, understanding and working with 3D printable models is an exciting and rewarding journey. We invite you to share your experiences, ask questions, and explore the vast potential that 3D printable models have to offer. Join the conversation, and together, let's unlock the future of 3D printing.