Intro

Discover the ultimate solution for industrial fastening needs with A&A Bolts high-quality fasteners. Our article explores the benefits of using premium-grade bolts, screws, and nuts in industrial applications, including enhanced durability, corrosion resistance, and improved safety. Learn how A&A Bolts products meet the highest standards of quality and reliability.

Fasteners are an essential component in various industrial applications, playing a crucial role in ensuring the structural integrity and reliability of equipment, machinery, and infrastructure. Among the numerous types of fasteners available, bolts are one of the most widely used due to their versatility and effectiveness. A&A Bolt is a renowned manufacturer of high-quality fasteners, catering to the diverse needs of industries such as construction, automotive, aerospace, and energy.

In the industrial sector, the use of substandard fasteners can have severe consequences, including equipment failure, downtime, and even safety hazards. Therefore, it is essential to select fasteners that meet stringent quality standards, ensuring optimal performance and durability. A&A Bolt's commitment to producing high-quality fasteners has earned the company a reputation as a trusted supplier among industry professionals.

Advantages of High-Quality Fasteners

High-quality fasteners offer several advantages in industrial applications, including:

- Enhanced structural integrity: High-quality fasteners ensure that equipment and machinery are securely assembled, reducing the risk of failure and downtime.

- Improved safety: Reliable fasteners prevent accidents and injuries caused by equipment malfunction or collapse.

- Increased efficiency: High-quality fasteners minimize the need for frequent replacements and repairs, optimizing production processes and reducing maintenance costs.

- Compliance with regulations: Many industries are subject to strict regulations and standards, which high-quality fasteners can help meet or exceed.

Factors Affecting Fastener Quality

Several factors contribute to the quality of fasteners, including:

- Material selection: The choice of material depends on the specific application, with factors such as corrosion resistance, strength, and durability being crucial considerations.

- Manufacturing process: The manufacturing process can significantly impact fastener quality, with techniques such as forging, machining, and heat treatment influencing the final product.

- Surface finish: The surface finish of fasteners can affect their performance, with options such as zinc plating, chrome plating, and powder coating offering varying levels of corrosion resistance and aesthetic appeal.

- Testing and inspection: Rigorous testing and inspection procedures ensure that fasteners meet the required standards, with certification from reputable organizations such as ISO and ASTM providing assurance of quality.

A&A Bolt's Product Range

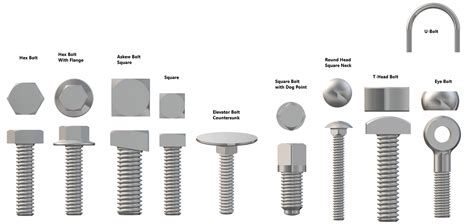

A&A Bolt offers a comprehensive range of high-quality fasteners, including:

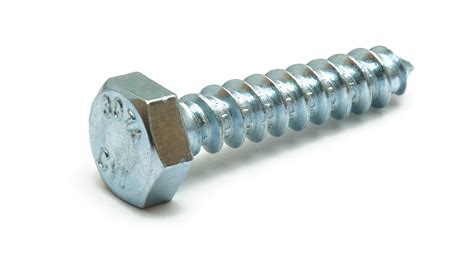

- Hex bolts: Available in various sizes and materials, hex bolts are suitable for a wide range of applications, from construction to automotive.

- Socket head bolts: With their cylindrical head and recessed socket, socket head bolts provide a secure and efficient fastening solution.

- Eye bolts: Featuring a ring or eye-shaped head, eye bolts are ideal for applications requiring a secure attachment point.

- Lag bolts: With their coarse threads and large diameter, lag bolts provide a strong and reliable fastening solution for heavy-duty applications.

Custom Fastener Solutions

A&A Bolt understands that each industry and application has unique requirements, and offers custom fastener solutions to meet these needs. With expertise in designing and manufacturing bespoke fasteners, A&A Bolt can provide:

- Custom material selection: A&A Bolt can work with clients to select the optimal material for their specific application.

- Specialized coatings: A&A Bolt offers various coating options, including zinc plating, chrome plating, and powder coating, to enhance corrosion resistance and aesthetic appeal.

- Modified fastener designs: A&A Bolt's design team can modify existing fastener designs or create new ones to meet specific requirements.

Benefits of Partnering with A&A Bolt

Partnering with A&A Bolt offers numerous benefits, including:

- Access to high-quality fasteners: A&A Bolt's commitment to quality ensures that clients receive the best possible fasteners for their applications.

- Expertise and support: A&A Bolt's experienced team provides expert advice and support, helping clients select the optimal fasteners for their needs.

- Custom solutions: A&A Bolt's custom fastener solutions enable clients to meet specific requirements and overcome unique challenges.

- Competitive pricing: A&A Bolt offers competitive pricing without compromising on quality, ensuring that clients receive the best value for their investment.

Conclusion

In conclusion, A&A Bolt is a trusted supplier of high-quality fasteners for industrial applications. With a commitment to quality, expertise in designing and manufacturing bespoke fasteners, and a comprehensive range of products, A&A Bolt is the ideal partner for industries seeking reliable and efficient fastening solutions.

Fastener Image Gallery

What is the difference between a hex bolt and a socket head bolt?

+A hex bolt has a hexagonal head, while a socket head bolt has a cylindrical head with a recessed socket.

What is the purpose of a lag bolt?

+A lag bolt is used for heavy-duty applications, providing a strong and reliable fastening solution.

Can A&A Bolt provide custom fastener solutions?

+Yes, A&A Bolt offers custom fastener solutions, including custom material selection, specialized coatings, and modified fastener designs.