Intro

Discover the 5 crucial components of aircraft fuel systems in the Air Force, ensuring safe and efficient flight operations. Learn about fuel tanks, pumps, filters, fuel lines, and fuel management systems, and how they work together to prevent fuel contamination, leaks, and system failures, guaranteeing optimal performance and crew safety.

The aircraft fuel system is a critical component of any aircraft, and its proper functioning is essential for the safe and efficient operation of the aircraft. In the Air Force, aircraft fuel systems are designed to meet the unique demands of military aviation, including high-performance flight, long-range missions, and rugged operating conditions. In this article, we will explore the 5 essential components of aircraft fuel systems in the Air Force.

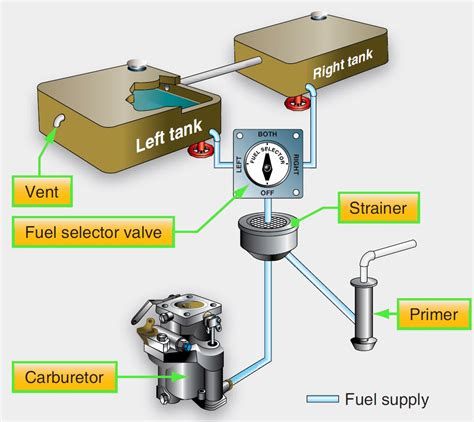

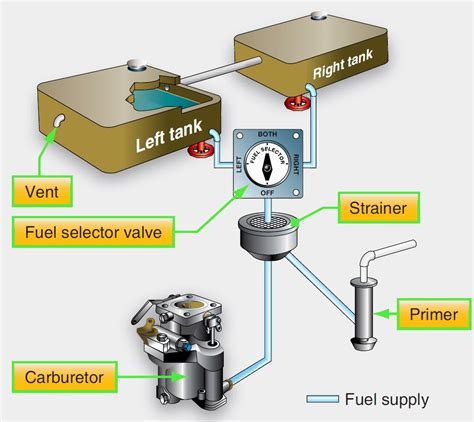

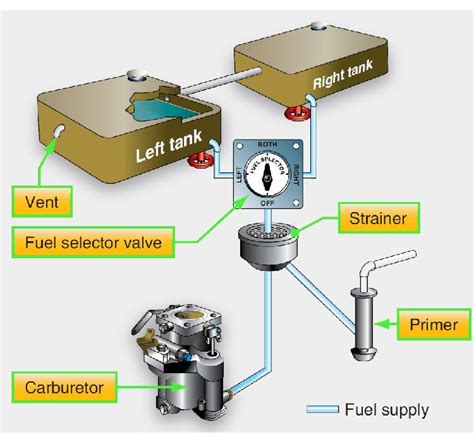

Fuel Tanks

The fuel tanks are the primary storage containers for fuel in an aircraft. In the Air Force, fuel tanks are designed to be lightweight, durable, and resistant to corrosion. They are typically made of aluminum or stainless steel and are designed to withstand the stresses of flight, including turbulence and high-G forces.

The fuel tanks are typically located in the wings, fuselage, and tail section of the aircraft, and are connected by a network of fuel lines and pumps. The fuel tanks are designed to be self-sealing, meaning that they can withstand small arms fire and other types of damage without leaking fuel.

Types of Fuel Tanks

There are several types of fuel tanks used in Air Force aircraft, including:

- Integral fuel tanks: These are fuel tanks that are built into the aircraft's structure, such as the wing tanks.

- Bag tanks: These are flexible fuel tanks that are installed in the aircraft's cargo bay or other compartments.

- External fuel tanks: These are fuel tanks that are mounted on the aircraft's external hardpoints, such as the wing pylons.

Fuel Pumps

The fuel pumps are responsible for pressurizing and circulating fuel throughout the aircraft's fuel system. In the Air Force, fuel pumps are designed to be high-pressure, high-flow pumps that can handle the demands of high-performance flight.

The fuel pumps are typically driven by the aircraft's engines or by an electric motor, and are designed to provide a constant flow of fuel to the engines, regardless of the aircraft's altitude, airspeed, or attitude.

Types of Fuel Pumps

There are several types of fuel pumps used in Air Force aircraft, including:

- Centrifugal pumps: These are high-flow pumps that use a centrifugal impeller to pressurize and circulate fuel.

- Positive displacement pumps: These are high-pressure pumps that use a piston or gear to pressurize and circulate fuel.

- Electric fuel pumps: These are high-pressure pumps that are driven by an electric motor and are used to provide fuel to the engines during startup and shutdown.

Fuel Filters

The fuel filters are designed to remove contaminants and debris from the fuel, ensuring that the fuel is clean and free of debris before it reaches the engines. In the Air Force, fuel filters are designed to be high-efficiency filters that can remove even the smallest particles from the fuel.

The fuel filters are typically located in the fuel lines, and are designed to be easy to replace and maintain. They are typically made of a high-efficiency filter medium, such as a ceramic or paper element, and are designed to capture particles as small as 10 microns.

Types of Fuel Filters

There are several types of fuel filters used in Air Force aircraft, including:

- Cartridge-style filters: These are high-efficiency filters that use a replaceable cartridge element to capture contaminants.

- Canister-style filters: These are high-efficiency filters that use a canister element to capture contaminants.

- Screen-style filters: These are simple filters that use a screen element to capture large particles and debris.

Fuel Meters

The fuel meters are designed to measure the fuel flow rate and provide an accurate indication of the fuel quantity in the tanks. In the Air Force, fuel meters are designed to be high-accuracy meters that can provide real-time data on fuel flow and quantity.

The fuel meters are typically located in the cockpit, and are designed to be easy to read and understand. They are typically made of a high-accuracy flow meter, such as a turbine or piston meter, and are designed to provide accurate data on fuel flow and quantity.

Types of Fuel Meters

There are several types of fuel meters used in Air Force aircraft, including:

- Mechanical fuel meters: These are simple meters that use a mechanical linkage to measure fuel flow and quantity.

- Electronic fuel meters: These are high-accuracy meters that use electronic sensors and computers to measure fuel flow and quantity.

- Digital fuel meters: These are high-accuracy meters that use digital sensors and computers to measure fuel flow and quantity.

Fuel Management Computers

The fuel management computers are designed to manage the fuel system and provide real-time data on fuel flow and quantity. In the Air Force, fuel management computers are designed to be high-performance computers that can provide accurate data on fuel flow and quantity, as well as control the fuel system's various components.

The fuel management computers are typically located in the cockpit, and are designed to be easy to use and understand. They are typically made of a high-performance computer, such as a digital signal processor or a field-programmable gate array, and are designed to provide accurate data on fuel flow and quantity.

Types of Fuel Management Computers

There are several types of fuel management computers used in Air Force aircraft, including:

- Digital fuel management computers: These are high-performance computers that use digital sensors and algorithms to manage the fuel system.

- Analog fuel management computers: These are simple computers that use analog sensors and algorithms to manage the fuel system.

- Hybrid fuel management computers: These are high-performance computers that use a combination of digital and analog sensors and algorithms to manage the fuel system.

Gallery of Aircraft Fuel Systems

Aircraft Fuel Systems Image Gallery

Frequently Asked Questions (FAQs)

What are the different types of fuel tanks used in Air Force aircraft?

+The different types of fuel tanks used in Air Force aircraft include integral fuel tanks, bag tanks, and external fuel tanks.

What is the purpose of the fuel filters in an aircraft fuel system?

+The purpose of the fuel filters is to remove contaminants and debris from the fuel, ensuring that the fuel is clean and free of debris before it reaches the engines.

What is the function of the fuel management computers in an aircraft fuel system?

+The function of the fuel management computers is to manage the fuel system and provide real-time data on fuel flow and quantity.

Final Thoughts

In conclusion, the aircraft fuel system is a critical component of any aircraft, and its proper functioning is essential for the safe and efficient operation of the aircraft. The 5 essential components of aircraft fuel systems in the Air Force include fuel tanks, fuel pumps, fuel filters, fuel meters, and fuel management computers. By understanding the functions and types of these components, aircraft maintenance personnel can ensure that the fuel system is operating properly and efficiently.