Intro

Optimize your vehicles performance with a better built fuel tank. Discover 5 expert tips for a fuel tank upgrade, including materials, design, and installation. Learn how to improve fuel efficiency, reduce emissions, and enhance overall engine performance with a high-quality fuel tank, featuring key terms: fuel tank design, fuel efficiency, and engine performance optimization.

When it comes to building a fuel tank, there are several factors to consider to ensure a safe and efficient design. A well-built fuel tank is crucial for various industries, including automotive, aerospace, and chemical processing. In this article, we will discuss five tips for building a better fuel tank.

Understanding the Importance of Fuel Tank Design

A fuel tank is a critical component of any vehicle or equipment that uses fuel to operate. A poorly designed fuel tank can lead to safety risks, environmental hazards, and equipment damage. On the other hand, a well-designed fuel tank can improve performance, reduce emissions, and increase efficiency.

Tip 1: Choose the Right Materials

The choice of materials for a fuel tank is crucial for its durability and safety. The most common materials used for fuel tanks are steel, aluminum, and plastic. Each material has its pros and cons, and the selection depends on the specific application and industry.

For example, steel fuel tanks are durable and can withstand high pressures, but they are also heavy and prone to corrosion. Aluminum fuel tanks, on the other hand, are lightweight and resistant to corrosion, but they can be more expensive. Plastic fuel tanks are lightweight and inexpensive, but they may not be suitable for high-pressure applications.

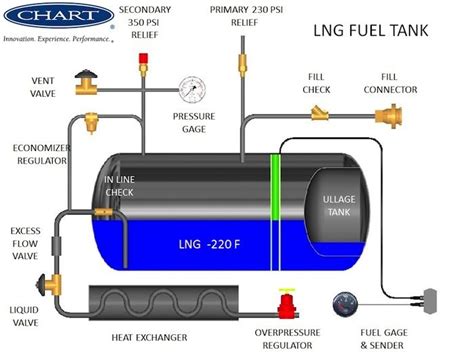

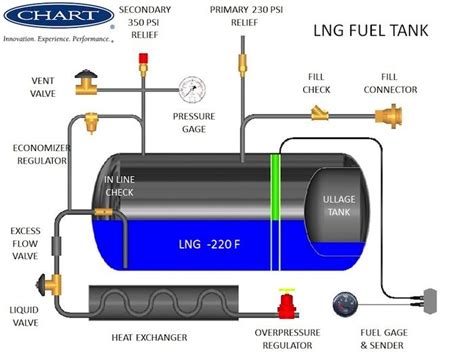

Tip 2: Consider the Shape and Size

The shape and size of a fuel tank are critical factors in its design. The tank should be designed to fit the available space and to minimize weight while maximizing capacity.

For example, a spherical fuel tank is ideal for high-pressure applications, as it can withstand stress evenly in all directions. A rectangular fuel tank, on the other hand, may be more suitable for low-pressure applications, as it can be designed to fit a specific space.

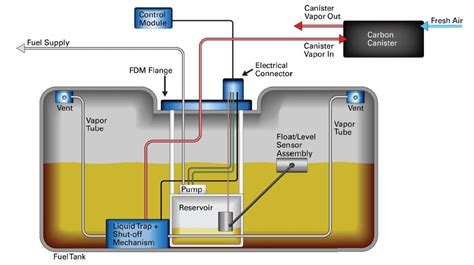

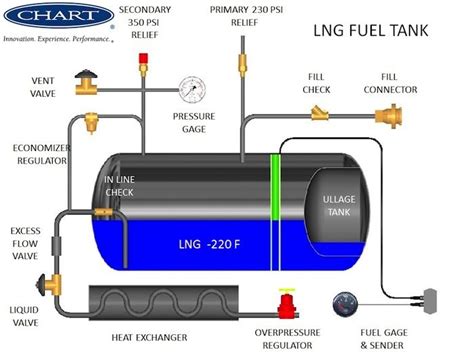

Tip 3: Ensure Proper Ventilation and Drainage

Proper ventilation and drainage are essential for a fuel tank to prevent the buildup of fumes and liquids. The tank should be designed with ventilation and drainage systems to ensure safe and efficient operation.

For example, a fuel tank should be designed with a vent pipe to allow air to enter and escape, preventing the buildup of fumes. The tank should also be designed with a drainage system to prevent the accumulation of liquids.

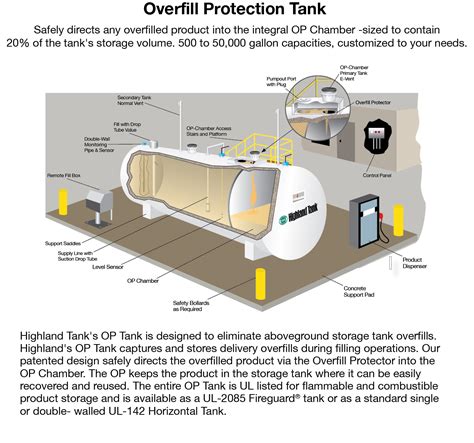

Tip 4: Implement Safety Features

Safety features are critical in fuel tank design to prevent accidents and ensure safe operation. The tank should be designed with safety features such as overflow protection, leak detection, and fire resistance.

For example, a fuel tank should be designed with an overflow protection system to prevent fuel from spilling over in case of an accident. The tank should also be designed with a leak detection system to alert operators of any leaks or damage.

Tip 5: Test and Inspect the Tank

Finally, it is essential to test and inspect the fuel tank to ensure its safe and efficient operation. The tank should be tested for leaks, corrosion, and other forms of damage.

For example, a fuel tank should be tested for leaks by pressurizing the tank and checking for any signs of leakage. The tank should also be inspected for corrosion and other forms of damage, and repaired or replaced as necessary.

Gallery of Fuel Tank Designs

Fuel Tank Designs

Frequently Asked Questions

What is the most common material used for fuel tanks?

+The most common material used for fuel tanks is steel.

What is the purpose of ventilation and drainage in fuel tank design?

+The purpose of ventilation and drainage in fuel tank design is to prevent the buildup of fumes and liquids.

What is the importance of testing and inspecting a fuel tank?

+Testing and inspecting a fuel tank is essential to ensure its safe and efficient operation.

By following these tips, you can design and build a fuel tank that is safe, efficient, and reliable. Remember to choose the right materials, consider the shape and size, ensure proper ventilation and drainage, implement safety features, and test and inspect the tank.