Intro

Master Eric Deming Seal techniques with 5 expert tips, enhancing dive safety, seal entry, and underwater navigation skills for scuba divers, improving overall diving experience.

The art of sealing with an Eric Deming seal is a nuanced and intricate process that requires attention to detail and a deep understanding of the tools and techniques involved. For those who are new to the world of Eric Deming seals, it can be overwhelming to navigate the various tips and tricks that are available. However, with the right guidance, anyone can master the art of sealing with an Eric Deming seal. In this article, we will explore five key tips for using an Eric Deming seal, and provide a comprehensive guide to help you get the most out of your sealing experience.

The importance of proper sealing techniques cannot be overstated. A well-sealed joint or connection can make all the difference in the performance and longevity of a system or machine. On the other hand, a poorly sealed joint can lead to leaks, damage, and even safety hazards. With an Eric Deming seal, you have the power to create strong, reliable seals that will withstand even the toughest conditions. But to do so, you need to understand the basics of sealing and how to use your Eric Deming seal effectively.

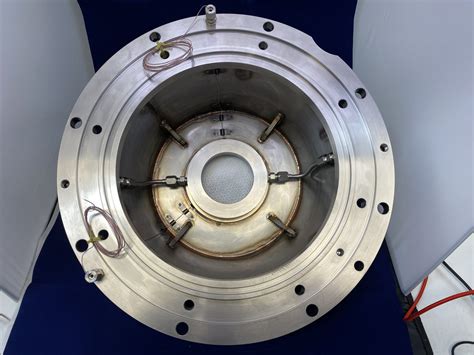

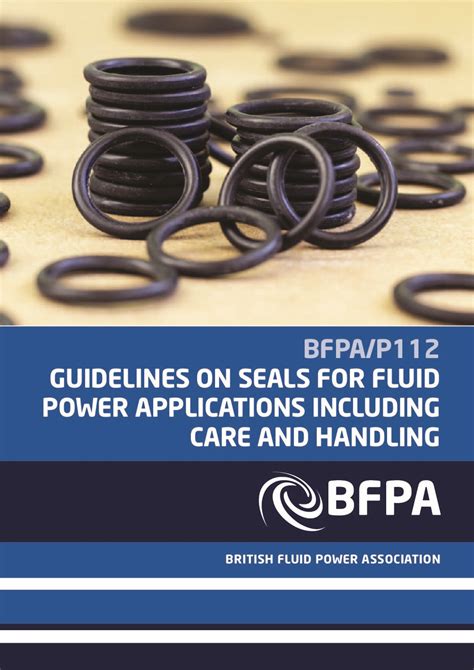

One of the key benefits of using an Eric Deming seal is its versatility. These seals can be used in a wide range of applications, from industrial machinery to automotive systems. They are also highly durable and resistant to wear and tear, making them a great choice for high-performance applications. However, to get the most out of your Eric Deming seal, you need to understand how to use it properly. This includes selecting the right seal for your application, preparing the surface for sealing, and applying the seal correctly.

Introduction to Eric Deming Seals

Benefits of Eric Deming Seals

The benefits of using an Eric Deming seal are numerous. They are highly durable and resistant to wear and tear, making them a great choice for high-performance applications. They are also versatile and can be used in a wide range of applications, from industrial machinery to automotive systems. Additionally, Eric Deming seals are relatively easy to install and maintain, making them a great choice for those who are new to the world of sealing.Tip 1: Choose the Right Seal

Factors to Consider

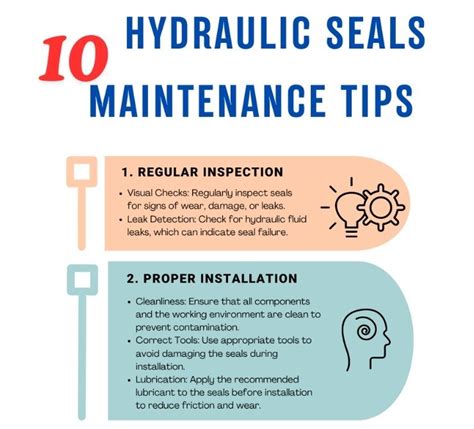

When choosing an Eric Deming seal, there are several factors to consider. These include the type of fluid or gas being sealed, the temperature and pressure of the system, and the materials being used. You should also consider the size and shape of the seal, as well as its durability and resistance to wear and tear. By taking the time to carefully consider these factors, you can select the right Eric Deming seal for your application and ensure a strong, reliable seal.Tip 2: Prepare the Surface

Importance of Surface Preparation

Surface preparation is a critical step in the sealing process. A well-prepared surface can make all the difference in the performance and longevity of the seal. By taking the time to carefully clean and prepare the surface, you can ensure a strong, reliable seal that will withstand even the toughest conditions. This includes using the right cleaning solutions and techniques, as well as inspecting the surface for any damage or wear.Tip 3: Apply the Seal Correctly

Common Mistakes to Avoid

When applying an Eric Deming seal, there are several common mistakes to avoid. These include applying too much or too little pressure, as well as misaligning the seal. By taking the time to carefully follow the manufacturer's instructions and ensure that the seal is properly seated and aligned, you can avoid these common mistakes and ensure a strong, reliable seal.Tip 4: Test the Seal

Importance of Testing

Testing is a critical step in the sealing process. By taking the time to carefully test the seal, you can ensure that it is functioning properly and that it will withstand even the toughest conditions. This includes using the right testing equipment and techniques, as well as inspecting the seal for any leaks or damage. By testing the seal, you can catch any potential problems before they become major issues.Tip 5: Maintain the Seal

Benefits of Maintenance

The benefits of maintaining an Eric Deming seal are numerous. By regularly inspecting the seal and making any necessary repairs or replacements, you can ensure that it continues to function properly and that it will withstand even the toughest conditions. This includes using the right maintenance equipment and techniques, as well as keeping the seal clean and free of debris. By maintaining the seal, you can extend its lifespan and ensure that it continues to provide a strong, reliable seal.Eric Deming Seal Image Gallery

What are the benefits of using an Eric Deming seal?

+The benefits of using an Eric Deming seal include its durability, reliability, and versatility. These seals are highly resistant to wear and tear, making them a great choice for high-performance applications. They are also relatively easy to install and maintain, making them a great choice for those who are new to the world of sealing.

How do I choose the right Eric Deming seal for my application?

+To choose the right Eric Deming seal for your application, you need to consider the specific requirements of your application, including the type of fluid or gas being sealed, the temperature and pressure of the system, and the materials being used. You should also consider the size and shape of the seal, as well as its durability and resistance to wear and tear.

How do I apply an Eric Deming seal correctly?

+To apply an Eric Deming seal correctly, you need to follow the manufacturer's instructions for application, as well as take the time to ensure that the seal is properly seated and aligned. You should also use the right tools and techniques, such as a seal installer or a hydraulic press.

How do I maintain an Eric Deming seal?

+To maintain an Eric Deming seal, you need to regularly inspect the seal for any signs of wear or damage, as well as make any necessary repairs or replacements. You should also use the right maintenance equipment and techniques, such as a seal conditioner or a lubricant.

What are some common mistakes to avoid when using an Eric Deming seal?

+Some common mistakes to avoid when using an Eric Deming seal include applying too much or too little pressure, as well as misaligning the seal. You should also avoid using the wrong type of seal for your application, as well as failing to properly maintain the seal.

In conclusion, using an Eric Deming seal requires attention to detail and a deep understanding of the tools and techniques involved. By following these five key tips, you can ensure a strong, reliable seal that will withstand even the toughest conditions. Whether you are a seasoned professional or just starting out, these tips will provide you with the guidance and expertise you need to get the most out of your sealing experience. So why wait? Start exploring the world of Eric Deming seals today and discover the benefits of a strong, reliable seal for yourself. We encourage you to comment below with any questions or feedback you may have, and to share this article with anyone who may be interested in learning more about Eric Deming seals.