Intro

Discover the intricacies of the F-15 fighter jet cost breakdown. Explore 6 key factors contributing to its multi-million dollar price tag, including development costs, production expenses, avionics, engine costs, and more. Get a detailed analysis of the economics behind this advanced military aircraft, and learn how its cost is justified by its unmatched performance and capabilities.

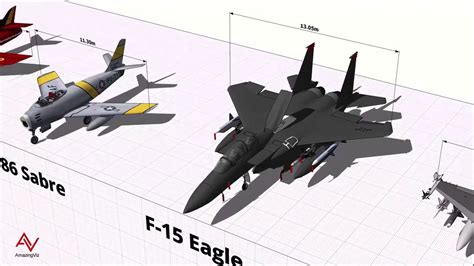

The F-15 fighter jet is one of the most iconic and technologically advanced military aircraft in the world. With its impressive performance capabilities and cutting-edge features, it's no surprise that the F-15 comes with a hefty price tag. But have you ever wondered what makes up the cost of this incredible machine? In this article, we'll break down the F-15 fighter jet cost into six key components, providing a deeper understanding of the investments required to design, develop, and deploy this powerful aircraft.

1. Research and Development (R&D) Costs

The research and development phase is a critical component of the F-15 fighter jet cost. This phase involves designing, testing, and refining the aircraft's systems, structures, and technologies. The R&D process requires significant investments in personnel, facilities, and equipment, which can drive up costs. According to various sources, the R&D costs for the F-15 program were estimated to be around $3 billion in the 1970s, which is equivalent to approximately $20 billion in today's dollars.

Challenges in R&D

The R&D phase of the F-15 program faced numerous challenges, including:

- Developing advanced aerodynamic designs and materials

- Integrating sophisticated avionics and radar systems

- Ensuring reliability and maintainability of complex systems

2. Production Costs

Once the R&D phase is complete, the production phase begins. This is where the aircraft is manufactured and assembled. The production costs of the F-15 include the expenses associated with:

- Procuring raw materials and components

- Assembling and integrating aircraft systems

- Conducting quality control and testing

The production cost of a single F-15 aircraft can range from $30 million to $50 million, depending on the variant and configuration.

Production Challenges

The production phase of the F-15 program has faced several challenges, including:

- Managing complex supply chains and logistics

- Ensuring consistent quality and reliability

- Implementing efficient manufacturing processes

3. Engine and Propulsion Costs

The engines and propulsion systems of the F-15 are among the most critical and expensive components. The F-15 is powered by two Pratt & Whitney F100-PW-229 engines, which provide a combined thrust of over 46,000 pounds. The cost of these engines can range from $10 million to $15 million per unit.

Engine and Propulsion Challenges

The development and production of the F-15's engines have presented several challenges, including:

- Achieving high thrust-to-weight ratios

- Ensuring reliable and efficient operation

- Meeting strict performance and safety standards

4. Avionics and Electronics Costs

The avionics and electronics systems of the F-15 are highly sophisticated and play a critical role in the aircraft's performance and capabilities. The costs of these systems can range from $5 million to $10 million per aircraft, depending on the configuration and complexity.

Avionics and Electronics Challenges

The development and integration of the F-15's avionics and electronics systems have presented several challenges, including:

- Ensuring seamless integration with other aircraft systems

- Meeting strict performance and reliability standards

- Implementing advanced software and algorithms

5. Maintenance and Upgrades Costs

The maintenance and upgrades costs of the F-15 are significant and ongoing. These costs include expenses associated with:

- Routine maintenance and repairs

- Upgrading aircraft systems and technologies

- Implementing new capabilities and features

The maintenance and upgrades costs of the F-15 can range from $5 million to $10 million per year, depending on the fleet size and operational requirements.

Maintenance and Upgrades Challenges

The maintenance and upgrades phase of the F-15 program has faced several challenges, including:

- Managing complex logistics and supply chains

- Ensuring consistent quality and reliability

- Implementing efficient maintenance processes

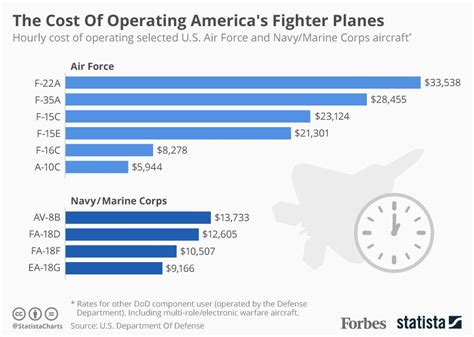

6. Operational Costs

The operational costs of the F-15 include expenses associated with:

- Fuel and energy consumption

- Pilot training and personnel costs

- Operating and maintaining airbases and infrastructure

The operational costs of the F-15 can range from $10 million to $20 million per year, depending on the fleet size and operational requirements.

Operational Challenges

The operational phase of the F-15 program has faced several challenges, including:

- Managing complex logistics and supply chains

- Ensuring consistent performance and reliability

- Implementing efficient operational processes

F-15 Fighter Jet Cost Gallery

What is the total cost of the F-15 fighter jet?

+The total cost of the F-15 fighter jet can range from $30 million to $50 million per unit, depending on the variant and configuration.

What are the main components of the F-15 fighter jet cost?

+The main components of the F-15 fighter jet cost include research and development costs, production costs, engine and propulsion costs, avionics and electronics costs, maintenance and upgrades costs, and operational costs.

What are the challenges faced by the F-15 program?

+The F-15 program has faced several challenges, including managing complex logistics and supply chains, ensuring consistent performance and reliability, and implementing efficient operational processes.

In conclusion, the F-15 fighter jet cost is a complex and multifaceted topic that involves various components and challenges. By breaking down the cost into six key components, we can gain a deeper understanding of the investments required to design, develop, and deploy this powerful aircraft. Whether you're a military enthusiast or simply interested in the world of aviation, the F-15 fighter jet is an impressive machine that continues to play a critical role in modern air power.