Intro

Boost site productivity and minimize risks with heavy equipment at work. Discover the importance of safety and efficiency in heavy machinery operation, and learn how to optimize equipment performance, reduce accidents, and improve workflow. Get expert tips on maintaining and operating heavy equipment for a safer and more productive work environment.

Operating heavy equipment is a crucial aspect of various industries, including construction, manufacturing, and mining. These machines play a vital role in increasing productivity and efficiency, but they also pose significant risks to operators and bystanders if not used properly. As such, it is essential to emphasize the importance of safety and efficiency when working with heavy equipment.

The consequences of accidents involving heavy equipment can be devastating, resulting in severe injuries, fatalities, and substantial financial losses. According to the Occupational Safety and Health Administration (OSHA), heavy equipment accidents account for a significant percentage of workplace fatalities in the United States. Moreover, the Bureau of Labor Statistics reports that the construction industry, which heavily relies on heavy equipment, has one of the highest rates of workplace fatalities.

Given the risks associated with heavy equipment operation, it is crucial to implement safety measures to minimize the likelihood of accidents. One of the most effective ways to ensure safety is to provide operators with comprehensive training. This training should cover the proper use of equipment, safety procedures, and emergency protocols. Regular maintenance and inspection of equipment are also vital to prevent malfunctions and ensure that machines are in good working condition.

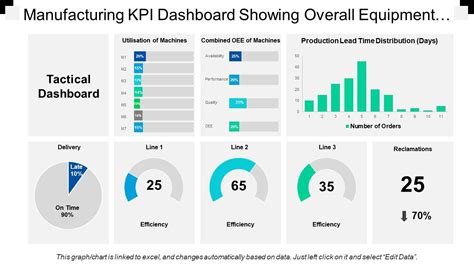

In addition to safety, efficiency is also a critical aspect of heavy equipment operation. When machines are used correctly, they can significantly increase productivity and reduce costs. However, inefficient use of equipment can lead to wasted time, resources, and energy. To optimize efficiency, operators should be aware of the equipment's capabilities and limitations, and use the right machine for the job.

Types of Heavy Equipment

There are various types of heavy equipment used in different industries, each designed for specific tasks. Some of the most common types of heavy equipment include:

Cranes

Cranes are used for lifting and moving heavy loads, and are commonly used in construction and manufacturing. There are different types of cranes, including tower cranes, mobile cranes, and overhead cranes.

Bulldozers

Bulldozers, also known as dozers, are used for moving earth and other materials. They are commonly used in construction, mining, and agriculture.

Excavators

Excavators, also known as diggers, are used for digging and moving earth. They are commonly used in construction, mining, and landscaping.

Loaders

Loaders, also known as front-end loaders, are used for loading and moving materials. They are commonly used in construction, mining, and agriculture.

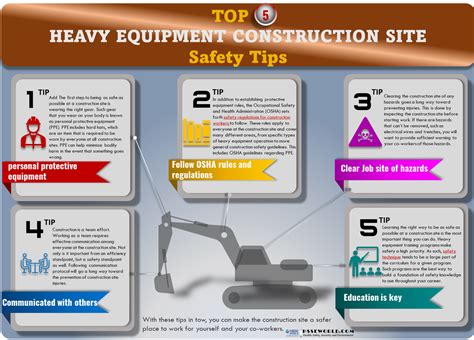

Safety Precautions

To ensure safety when working with heavy equipment, operators and bystanders should follow these safety precautions:

Personal Protective Equipment

Operators should wear personal protective equipment (PPE) such as hard hats, safety glasses, and earplugs to prevent injuries.

Pre-Operational Checks

Operators should perform pre-operational checks to ensure that the equipment is in good working condition.

Safe Operating Procedures

Operators should follow safe operating procedures, such as using the correct lifting techniques and maintaining a safe distance from other equipment and personnel.

Regular Maintenance

Equipment should be regularly maintained to prevent malfunctions and ensure that machines are in good working condition.

Efficiency Tips

To optimize efficiency when working with heavy equipment, operators should follow these tips:

Use the Right Equipment

Operators should use the right equipment for the job to avoid wasting time and resources.

Plan the Job

Operators should plan the job to ensure that the equipment is used efficiently and effectively.

Use Technology

Operators should use technology, such as GPS and automation, to optimize efficiency and productivity.

Maintain Equipment

Operators should regularly maintain equipment to prevent malfunctions and ensure that machines are in good working condition.

Gallery of Heavy Equipment

Heavy Equipment Image Gallery

What are the most common types of heavy equipment?

+The most common types of heavy equipment include cranes, bulldozers, excavators, and loaders.

What are the safety precautions that should be taken when working with heavy equipment?

+Operators should wear personal protective equipment, perform pre-operational checks, follow safe operating procedures, and maintain equipment regularly.

How can efficiency be optimized when working with heavy equipment?

+Operators should use the right equipment for the job, plan the job, use technology, and maintain equipment regularly.

In conclusion, operating heavy equipment requires a focus on both safety and efficiency. By following safety precautions and optimizing efficiency, operators can minimize the risks associated with heavy equipment operation and increase productivity. As the construction industry continues to grow, it is essential to emphasize the importance of safety and efficiency in heavy equipment operation.