Intro

Discover the fascinating art of crayon making in our in-depth guide. Learn the step-by-step process of transforming paraffin wax, pigments, and binders into vibrant, colorful crayons. From mixing and melting to molding and quality control, explore the intricacies of crayon manufacturing and uncover the secrets behind these beloved art supplies.

Crayons have been a staple in every child's creative journey, providing a world of colorful possibilities on paper, canvas, and even walls (much to the chagrin of many a parent!). But have you ever stopped to think about how these wax wonders are made? From the early beginnings of crayon production to the intricate processes of modern manufacturing, we're about to take a fascinating journey into the world of crayon making.

History of Crayon Making

Believe it or not, the earliest recorded evidence of crayon-like writing instruments dates back to ancient civilizations in Egypt, Greece, and Rome. These early crayons were made from a mixture of charcoal, fat, and pigments, allowing artists to create vibrant works on a variety of surfaces. Fast forward to the 18th century, when French art suppliers began producing the first commercial crayons, and the modern crayon was born.

Materials Used in Crayon Making

Before we dive into the manufacturing process, let's take a look at the key ingredients used to make crayons:

- Paraffin wax: The main component of crayons, paraffin wax provides the structure and durability needed for a good crayon.

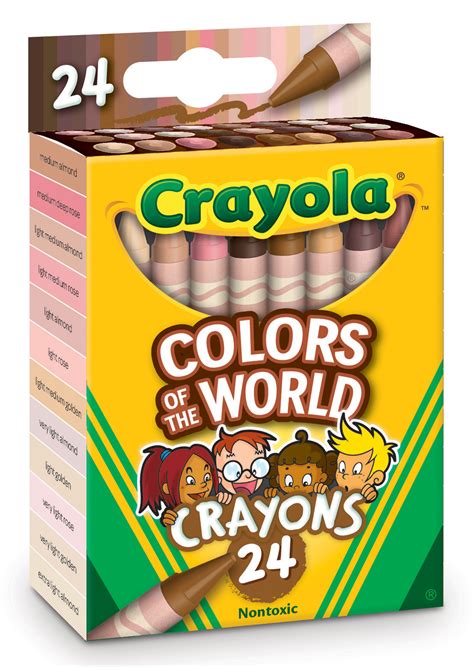

- Pigments: Various pigments, such as carbon black, iron oxide, and titanium dioxide, are used to create the wide range of colors available.

- Fillers: Silica, talc, or other fillers are added to improve the strength and durability of the crayon.

- Binders: Resins or other binding agents are used to hold the pigment particles together.

- Fats and oils: Some crayons may include small amounts of fats or oils to improve their texture and consistency.

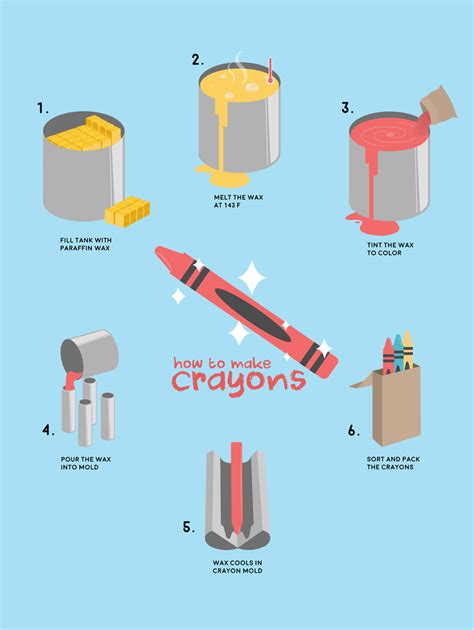

The Crayon Making Process

Now that we've covered the history and materials, let's explore the step-by-step process of making crayons:

- Wax Melting: The first step involves melting the paraffin wax in large kettles or vats. The wax is heated until it reaches a temperature of around 180°F (82°C), creating a smooth, uniform liquid.

- Color Mixing: The pigments, fillers, and binders are then added to the melted wax and thoroughly mixed to create the desired color.

- Crayon Shaping: The colored wax mixture is then poured into molds, which can be made from a variety of materials, including metal, plastic, or silicone.

- Cooling and Hardening: The wax is allowed to cool and harden in the mold, a process that can take anywhere from a few minutes to several hours, depending on the size of the crayon.

- Removing from Mold: Once hardened, the crayon is removed from the mold and excess wax is trimmed from the edges.

- Quality Control: Crayons are then inspected for quality and texture, with any defects or irregularities removed from the production line.

Modern Crayon Manufacturing

While the basic process of crayon making remains relatively unchanged, modern manufacturing techniques have introduced new efficiencies and innovations:

- Automated machinery: Many crayon manufacturers now use automated machines to streamline the process, from wax melting to crayon shaping.

- Computerized color matching: Advanced computer software allows manufacturers to precisely match colors and create new shades with ease.

- Environmental considerations: Many manufacturers are now exploring eco-friendly alternatives, such as using soy wax or recycled materials in their crayons.

Fun Facts and Variations

- Glow-in-the-dark crayons: Some manufacturers add special pigments to create glow-in-the-dark crayons, perfect for kids who love to draw in the dark.

- Scented crayons: Some crayons are infused with fragrances, adding an extra sensory dimension to the coloring experience.

- Metallic crayons: Metallic powders can be added to create shimmering, metallic effects.

Conclusion: The Art of Crayon Making

As we've discovered, the process of making crayons is a fascinating blend of art, science, and tradition. From the early beginnings of crayon production to the modern manufacturing techniques, the world of crayons continues to evolve and inspire creativity in children and adults alike.

Crayon Making Gallery

What are crayons made of?

+Crayons are made from a mixture of paraffin wax, pigments, fillers, and binders.

How are crayons colored?

+Crayons are colored by adding pigments to the melted wax mixture.

What is the history of crayon making?

+The history of crayon making dates back to ancient civilizations, with modern commercial production beginning in the 18th century.

We hope you've enjoyed this journey into the world of crayon making! Whether you're a nostalgic adult or a curious child, there's no denying the magic of these colorful sticks.