Intro

Discover the fascinating world of Stirling engines! Learn how these innovative machines work through 5 key principles, leveraging heat transfer, thermodynamics, and mechanical advantage. From heating and cooling to power generation, explore the science behind Stirling engines and their potential applications in renewable energy, transportation, and more.

Stirling engines have been a topic of interest for many years, and their unique characteristics make them an attractive alternative to traditional internal combustion engines. But have you ever wondered how they work? In this article, we will delve into the world of Stirling engines and explore the five ways they operate.

Stirling engines are heat engines that use a sealed system to convert heat energy into mechanical energy. They are highly efficient and can run on a wide range of heat sources, including solar, biomass, and waste heat. But what makes them tick?

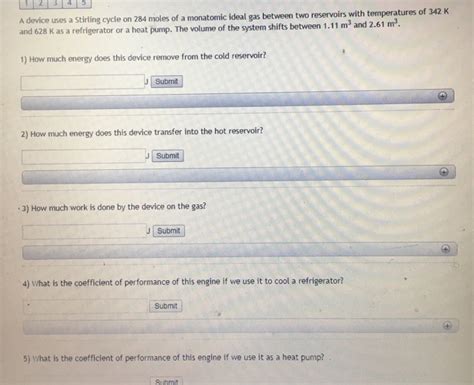

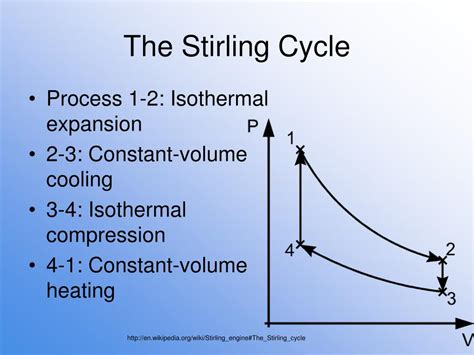

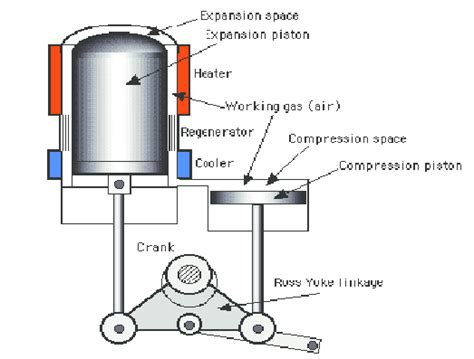

1. The Stirling Cycle

The Stirling cycle is the fundamental principle behind the operation of Stirling engines. It consists of four stages: isothermal expansion, isentropic expansion, isothermal compression, and isentropic compression. During these stages, the working fluid (usually a gas) is heated and expanded, producing work, and then cooled and compressed, ready to start the cycle again.

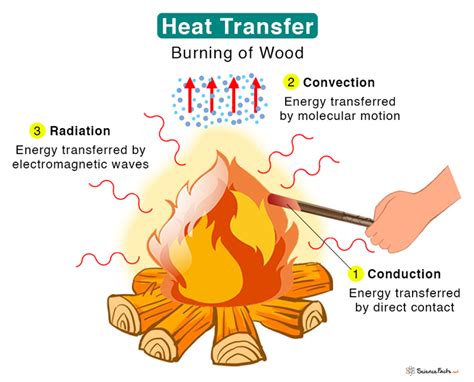

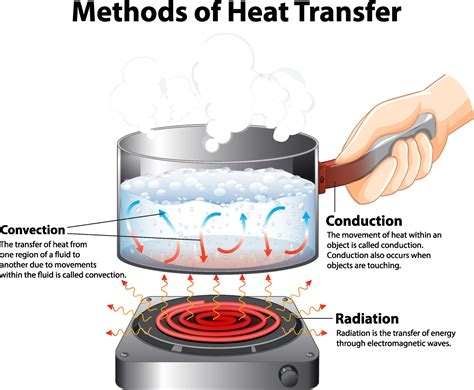

2. Heat Transfer

Heat transfer is a critical aspect of Stirling engine operation. The engine uses a heat exchanger to transfer heat from the external source to the working fluid. This heat energy is then converted into mechanical energy through the Stirling cycle. The efficiency of the heat transfer process is crucial in determining the overall efficiency of the engine.

3. Regeneration

Regeneration is another key feature of Stirling engines. During the compression stage, the working fluid is cooled, and the heat is transferred to a regenerator, which stores the heat energy. This stored heat is then used to pre-heat the working fluid during the expansion stage, increasing the efficiency of the engine.

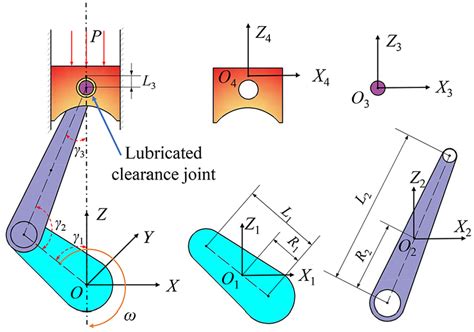

4. Piston Motion

The piston motion in a Stirling engine is a critical aspect of its operation. The piston moves up and down in the cylinder, driven by the pressure difference between the hot and cold spaces. This motion is converted into rotary motion through a crankshaft, producing the mechanical energy output.

5. Power Output

Finally, the power output of a Stirling engine is determined by the efficiency of the engine and the heat input. The engine produces a smooth, quiet, and vibration-free power output, making it suitable for a wide range of applications, from small-scale power generation to large-scale industrial applications.

In conclusion, Stirling engines work through a combination of the Stirling cycle, heat transfer, regeneration, piston motion, and power output. Their unique characteristics make them an attractive alternative to traditional internal combustion engines, and their applications continue to grow.

Now that you know the five ways Stirling engines work, we invite you to share your thoughts and experiences with Stirling engines. Have you ever worked with a Stirling engine? Do you have any questions about their operation? Share your comments below!

Stirling Engine Image Gallery

What is a Stirling engine?

+A Stirling engine is a type of heat engine that uses a sealed system to convert heat energy into mechanical energy.

How does a Stirling engine work?

+A Stirling engine works through a combination of the Stirling cycle, heat transfer, regeneration, piston motion, and power output.

What are the advantages of Stirling engines?

+Stirling engines have several advantages, including high efficiency, quiet operation, and vibration-free power output.