Intro

Master the art of MIG welding with our expert guide. Discover the top 5 essential ways to improve your MIG welding skills, including proper equipment setup, shielding gas techniques, and optimizing weld speed. Boost your welding confidence and achieve professional results with our actionable tips and tricks, tailored for both beginners and seasoned welders.

Mastering MIG (Metal Inert Gas) welding is a valuable skill that can be applied in various industries, including automotive, construction, and manufacturing. With the right techniques and practices, you can produce high-quality welds that meet the demands of your profession. In this article, we will explore the essential ways to master MIG welding.

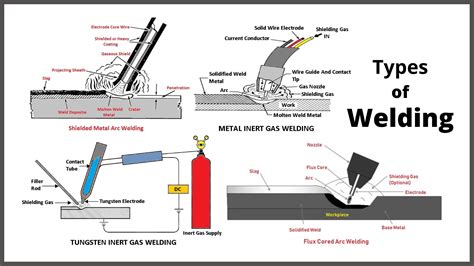

Understanding the Basics of MIG Welding

Before diving into the essential ways to master MIG welding, it's crucial to understand the basics. MIG welding is a type of arc welding that uses a continuous wire feed as the electrode. The wire is fed through a gun, which is connected to a power source. The arc is created when the wire comes into contact with the workpiece, melting the metal and creating a strong bond.

1. Choose the Right Equipment

Having the right equipment is essential for mastering MIG welding. The equipment you need includes a MIG welder, welding gun, wire feed, and shielding gas. The MIG welder should be capable of producing a consistent arc, and the welding gun should be comfortable to hold and maneuver.

Selecting the Right Wire and Shielding Gas

The type of wire and shielding gas you use can significantly affect the quality of your welds. The wire should be compatible with the metal you are welding, and the shielding gas should be suitable for the type of weld you are making. Common types of wire used in MIG welding include ER70S-6 and ER80S-D2.

Wire Selection Criteria

- Material compatibility

- Thickness and strength

- Corrosion resistance

- Welding position

Shielding Gas Selection Criteria

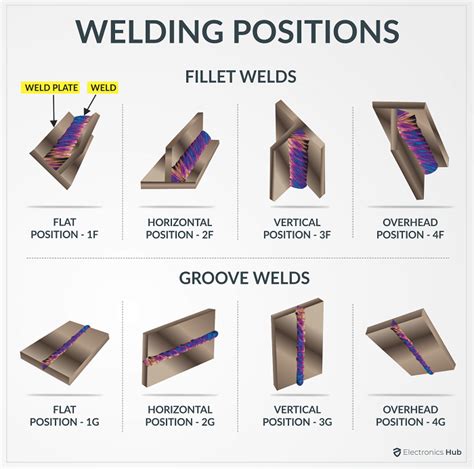

- Type of weld (flat, horizontal, vertical, or overhead)

- Material thickness

- Welding speed

- Shielding gas flow rate

2. Develop Good Welding Techniques

Good welding techniques are essential for producing high-quality welds. This includes maintaining a consistent arc length, using the correct welding angle, and applying the right amount of heat.

Tips for Improving Welding Techniques

- Practice regularly to develop muscle memory

- Use a consistent arc length and welding angle

- Apply the right amount of heat to avoid overheating or underheating

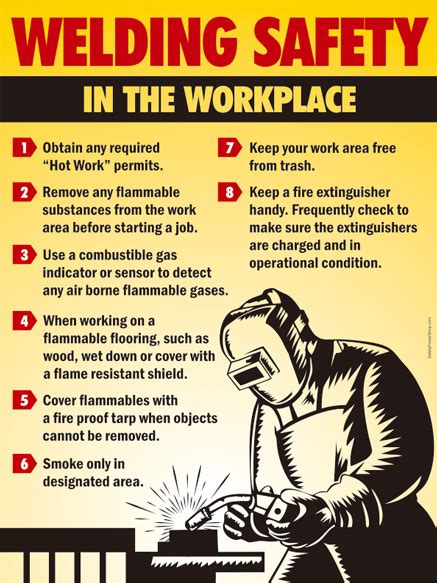

- Use a welding helmet with a shaded lens to protect your eyes

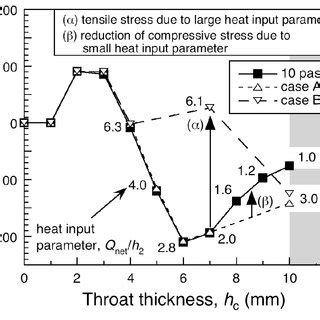

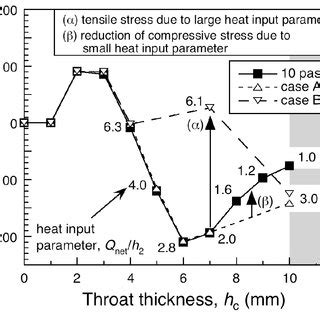

3. Learn to Control the Heat Input

Controlling the heat input is critical in MIG welding. Too much heat can cause the metal to warp or distort, while too little heat can result in a weak weld.

Factors Affecting Heat Input

- Welding current and voltage

- Wire feed speed

- Arc length

- Shielding gas flow rate

Tips for Controlling Heat Input

- Use a welding machine with a variable heat control

- Adjust the welding current and voltage according to the material thickness

- Monitor the arc length and adjust as necessary

- Use a shielding gas with a high flow rate to dissipate heat

4. Practice Welding in Different Positions

Welding in different positions can be challenging, but it's essential to master MIG welding. Practice welding in flat, horizontal, vertical, and overhead positions to develop your skills.

Tips for Welding in Different Positions

- Use a welding helmet with a shaded lens to protect your eyes

- Adjust the welding angle and arc length according to the position

- Apply the right amount of heat to avoid overheating or underheating

- Use a welding machine with a variable heat control

5. Join a Welding Community or Take Classes

Joining a welding community or taking classes can help you improve your MIG welding skills. You can learn from experienced welders, get feedback on your techniques, and stay updated on the latest technologies and techniques.

Benefits of Joining a Welding Community or Taking Classes

- Learn from experienced welders

- Get feedback on your techniques

- Stay updated on the latest technologies and techniques

- Network with other welders and potential employers

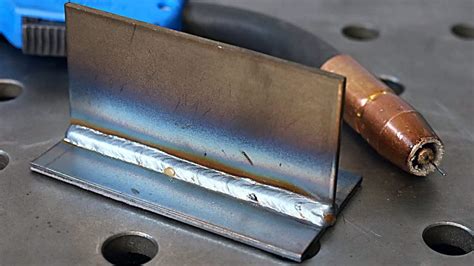

Mig Welding Image Gallery

What is MIG welding?

+MIG (Metal Inert Gas) welding is a type of arc welding that uses a continuous wire feed as the electrode.

What is the difference between MIG and TIG welding?

+MIG welding uses a continuous wire feed, while TIG (Tungsten Inert Gas) welding uses a non-consumable tungsten electrode.

What are the benefits of MIG welding?

+MIG welding is faster and more efficient than other types of welding, and it produces high-quality welds with minimal distortion.

We hope this article has provided you with the essential ways to master MIG welding. Remember to practice regularly, develop good welding techniques, learn to control the heat input, practice welding in different positions, and join a welding community or take classes to improve your skills. With dedication and hard work, you can become a skilled MIG welder and produce high-quality welds that meet the demands of your profession.