Intro

Discover how Lockheed Martin is transforming aircraft skin technology with innovative solutions. Learn about 5 revolutionary advancements, including advanced materials, aerodynamic design, and integrated sensing systems, that enhance aircraft performance, durability, and sustainability, redefining the future of flight and setting new standards for aerospace engineering.

The aircraft industry is constantly evolving, with new technologies and innovations emerging every year. One area that has seen significant advancements in recent years is aircraft skin technology. Lockheed Martin, a leading aerospace and defense company, has been at the forefront of this revolution, developing cutting-edge materials and designs that are transforming the way aircraft are built and operated. In this article, we will explore five ways Lockheed Martin is revolutionizing aircraft skin technology.

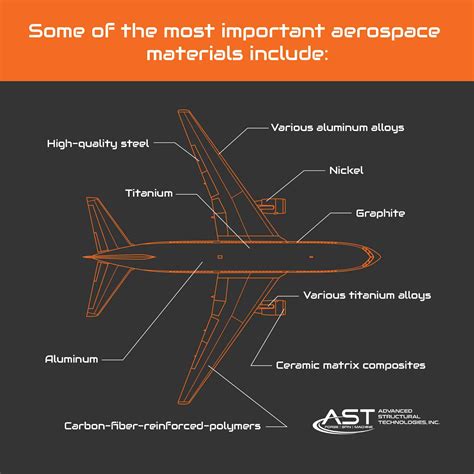

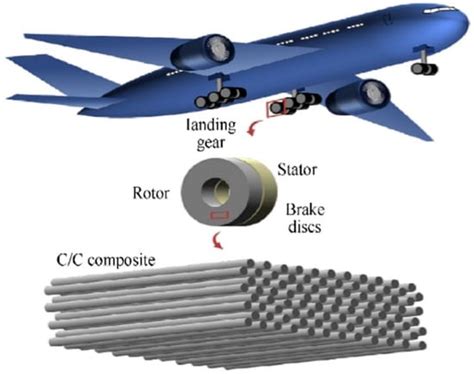

1. Advanced Materials

Lockheed Martin has been investing heavily in the development of advanced materials that can withstand the harsh conditions of flight. These materials include advanced composites, such as carbon fiber reinforced polymers (CFRP), which are lighter and stronger than traditional metals. Lockheed Martin has also developed new metal alloys that are more resistant to corrosion and fatigue. These advanced materials are being used in the production of aircraft skin, allowing for significant weight reductions and improved durability.

Benefits of Advanced Materials

- Reduced weight: Advanced materials are lighter than traditional metals, reducing the overall weight of the aircraft and improving fuel efficiency.

- Improved durability: Advanced materials are more resistant to corrosion and fatigue, reducing the need for maintenance and repairs.

- Increased strength: Advanced materials are stronger than traditional metals, allowing for more efficient use of materials and improved safety.

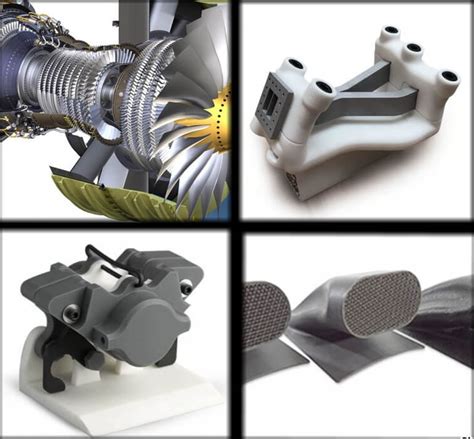

2. 3D Printing

Lockheed Martin has been at the forefront of 3D printing technology, using it to produce complex aircraft components, including skin panels. 3D printing allows for the rapid production of parts with complex geometries, reducing the need for tooling and molds. Lockheed Martin has developed advanced 3D printing techniques that allow for the production of large, complex parts, such as aircraft skin panels.

Benefits of 3D Printing

- Rapid production: 3D printing allows for the rapid production of parts, reducing lead times and improving production efficiency.

- Complex geometries: 3D printing allows for the production of complex parts with intricate geometries, reducing the need for assembly and improving structural integrity.

- Reduced waste: 3D printing reduces waste by producing parts directly from digital designs, eliminating the need for tooling and molds.

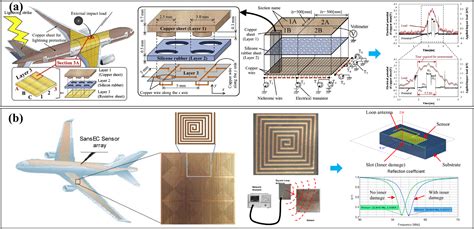

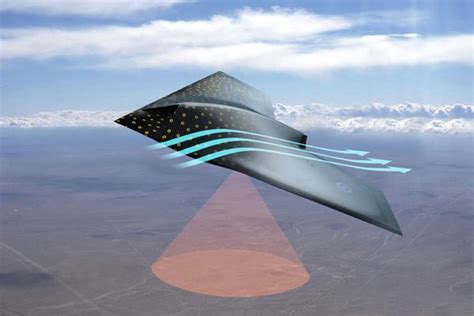

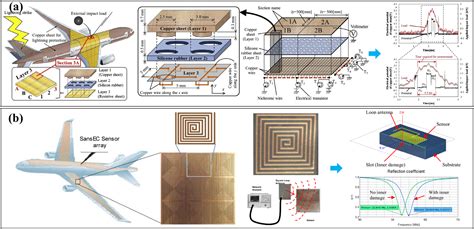

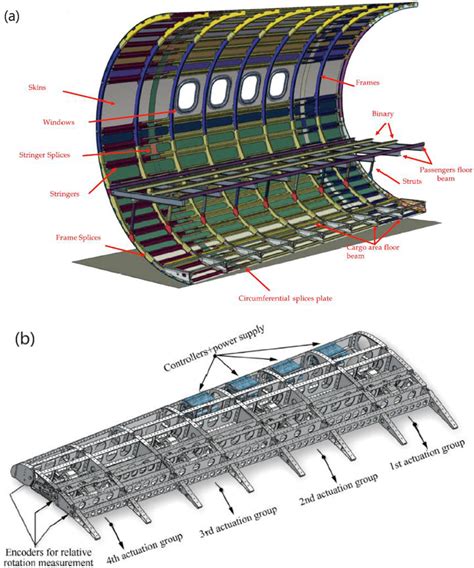

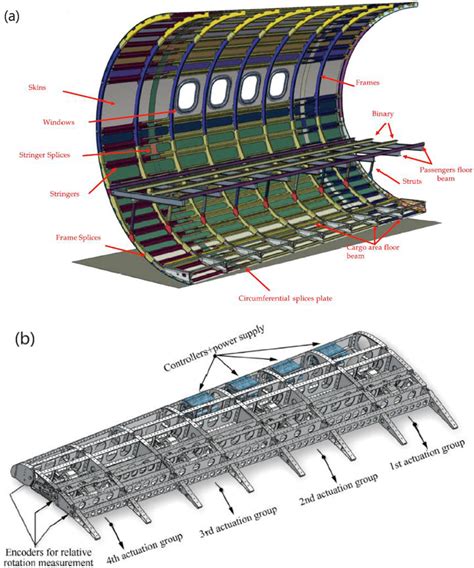

3. Smart Skins

Lockheed Martin has been developing advanced "smart skin" technologies that can detect and respond to changing environmental conditions. These smart skins are equipped with sensors and actuators that can detect changes in temperature, humidity, and other environmental factors, allowing the aircraft to adapt and respond accordingly.

Benefits of Smart Skins

- Improved safety: Smart skins can detect and respond to changing environmental conditions, improving safety and reducing the risk of accidents.

- Increased efficiency: Smart skins can optimize aircraft performance by adapting to changing environmental conditions, improving fuel efficiency and reducing emissions.

- Reduced maintenance: Smart skins can detect and diagnose problems, reducing the need for maintenance and repairs.

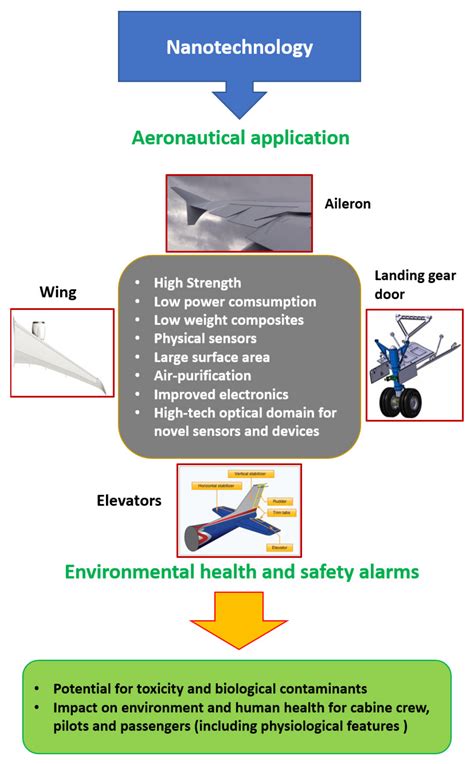

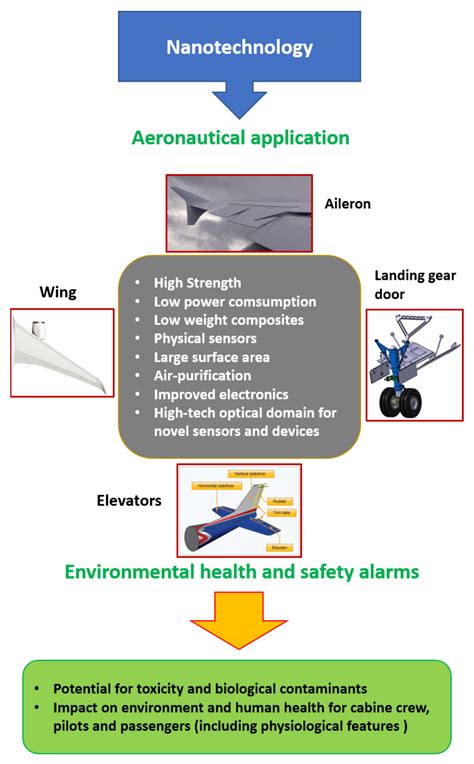

4. Nanomaterials

Lockheed Martin has been exploring the use of nanomaterials in aircraft skin technology. Nanomaterials are materials with dimensions on the nanometer scale, offering unique properties such as increased strength, reduced weight, and improved durability. Lockheed Martin has been developing nanomaterials that can be used in aircraft skin, allowing for significant weight reductions and improved performance.

Benefits of Nanomaterials

- Reduced weight: Nanomaterials are lighter than traditional materials, reducing the overall weight of the aircraft and improving fuel efficiency.

- Improved durability: Nanomaterials are more resistant to corrosion and fatigue, reducing the need for maintenance and repairs.

- Increased strength: Nanomaterials are stronger than traditional materials, allowing for more efficient use of materials and improved safety.

5. Advanced Manufacturing

Lockheed Martin has been investing in advanced manufacturing technologies, such as automation and robotics, to improve the production of aircraft skin. These technologies allow for the rapid production of high-quality parts, reducing lead times and improving production efficiency.

Benefits of Advanced Manufacturing

- Rapid production: Advanced manufacturing technologies allow for the rapid production of parts, reducing lead times and improving production efficiency.

- Improved quality: Advanced manufacturing technologies allow for the production of high-quality parts, reducing the need for inspections and repairs.

- Reduced waste: Advanced manufacturing technologies reduce waste by producing parts directly from digital designs, eliminating the need for tooling and molds.

Aircraft Skin Technology Image Gallery

What is aircraft skin technology?

+Aircraft skin technology refers to the materials and designs used to construct the outer layer of an aircraft. It is a critical component of an aircraft's structure, providing strength, durability, and aerodynamic performance.

What are the benefits of advanced materials in aircraft skin technology?

+Advanced materials offer several benefits, including reduced weight, improved durability, and increased strength. These benefits can lead to improved fuel efficiency, reduced maintenance, and enhanced safety.

What is 3D printing and how is it used in aircraft skin technology?

+3D printing is a manufacturing technology that allows for the rapid production of complex parts. In aircraft skin technology, 3D printing is used to produce parts with complex geometries, reducing the need for tooling and molds.

We hope this article has provided valuable insights into the innovative work being done by Lockheed Martin in the field of aircraft skin technology. From advanced materials to smart skins, the company is pushing the boundaries of what is possible in the design and construction of aircraft. As the industry continues to evolve, it will be exciting to see how these technologies are applied in the years to come.