Intro

Unlock a career in non-destructive testing (NDT) and discover the techniques used to inspect and evaluate materials without causing damage. Learn about NDT methods like radiography, ultrasonic testing, and magnetic particle testing, and explore the job roles, industries, and growth opportunities in this specialized field of quality control and assurance.

A career in non-destructive testing (NDT) can be a highly rewarding and challenging profession for those who are interested in science, technology, engineering, and mathematics (STEM) fields. NDT is a crucial process used to evaluate the properties and integrity of materials, components, and systems without causing damage. In this article, we will delve into the world of NDT, exploring its importance, various techniques, and the career paths available to those who are interested in pursuing a career in this field.

What is Non-Destructive Testing?

Non-destructive testing is a broad term that encompasses a range of techniques used to examine the properties and integrity of materials, components, and systems without causing damage. NDT is used in various industries, including aerospace, automotive, oil and gas, and construction, to name a few. The primary goal of NDT is to detect defects, flaws, or discontinuities in materials or components, which can affect their performance, safety, or reliability.

Importance of Non-Destructive Testing

NDT plays a critical role in ensuring the safety, quality, and reliability of materials, components, and systems. By detecting defects or flaws early on, NDT can help prevent catastrophic failures, reduce maintenance costs, and extend the lifespan of equipment and infrastructure. In industries such as aerospace and nuclear, NDT is crucial for ensuring the safety of people and equipment.

Types of Non-Destructive Testing Techniques

There are several types of NDT techniques, each with its own advantages and limitations. Some of the most common NDT techniques include:

- Visual Testing (VT): This involves visually examining the surface of a material or component to detect defects or irregularities.

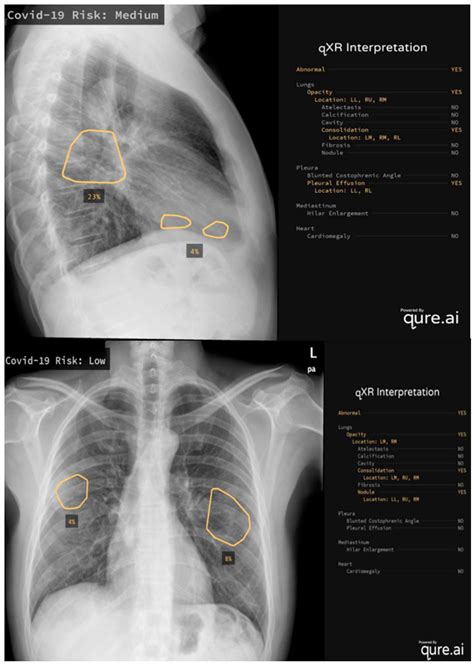

- Radiography (RT): This technique uses X-rays or gamma rays to produce images of the internal structure of a material or component.

- Ultrasonic Testing (UT): This method uses high-frequency sound waves to detect defects or irregularities in materials or components.

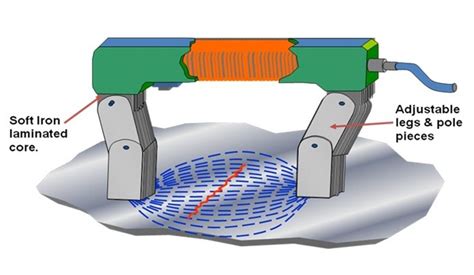

- Magnetic Particle Testing (MT): This technique uses magnetic fields to detect defects or irregularities in ferromagnetic materials.

- Liquid Penetrant Testing (PT): This method uses a liquid penetrant to detect surface-breaking defects or irregularities in materials or components.

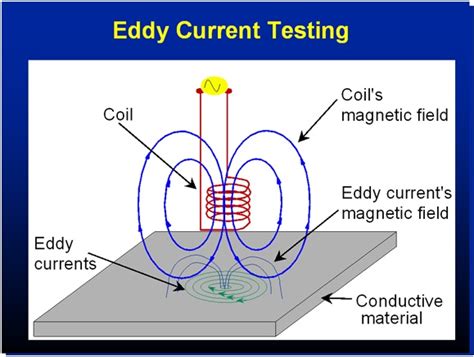

- Eddy Current Testing (ET): This technique uses electromagnetic fields to detect defects or irregularities in conductive materials.

Career Paths in Non-Destructive Testing

A career in NDT can be highly rewarding, with various career paths available to those who are interested in pursuing a career in this field. Some of the most common career paths in NDT include:

- NDT Technician: NDT technicians are responsible for performing NDT tests and inspections on materials, components, and systems.

- NDT Inspector: NDT inspectors are responsible for evaluating the results of NDT tests and inspections and making recommendations for repair or replacement.

- NDT Engineer: NDT engineers are responsible for designing and developing NDT equipment and techniques.

- NDT Consultant: NDT consultants provide expert advice and guidance on NDT techniques and equipment to industries and organizations.

- NDT Instructor: NDT instructors teach NDT courses and training programs to students and professionals.

Education and Training Requirements

To pursue a career in NDT, you will typically need to have a strong foundation in science, technology, engineering, and mathematics (STEM) fields. Many NDT professionals hold a bachelor's degree in a relevant field, such as engineering, physics, or materials science. In addition to formal education, NDT professionals also require specialized training and certification in NDT techniques and equipment.

Certification and Qualification

NDT professionals can obtain certification and qualification through various organizations, such as the American Society for Nondestructive Testing (ASNT) and the International Institute of Welding (IIW). Certification and qualification programs typically involve a combination of education, training, and experience, as well as passing a written examination.

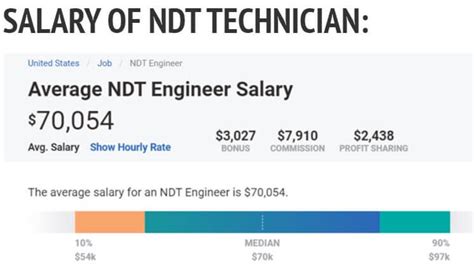

Salary and Job Outlook

The salary and job outlook for NDT professionals can vary depending on factors such as location, industry, and level of experience. According to the Bureau of Labor Statistics, the median annual salary for NDT technicians was around $62,000 in May 2020. The job outlook for NDT professionals is also positive, with the Bureau of Labor Statistics predicting a 10% growth in employment opportunities from 2020 to 2030.

Challenges and Opportunities

NDT professionals face a range of challenges, including the need to stay up-to-date with new technologies and techniques, as well as the need to work in a variety of environments and industries. However, NDT professionals also have many opportunities, including the chance to work on a wide range of projects, from aerospace to construction, and the opportunity to work with a variety of materials and equipment.

Conclusion

A career in non-destructive testing can be a highly rewarding and challenging profession for those who are interested in science, technology, engineering, and mathematics (STEM) fields. With various career paths available, including NDT technician, NDT inspector, NDT engineer, NDT consultant, and NDT instructor, there are many opportunities for those who are interested in pursuing a career in NDT. With the right education, training, and certification, NDT professionals can enjoy a positive job outlook and a competitive salary.

Non-Destructive Testing Image Gallery

What is non-destructive testing?

+Non-destructive testing is a range of techniques used to evaluate the properties and integrity of materials, components, and systems without causing damage.

What are the different types of non-destructive testing techniques?

+There are several types of non-destructive testing techniques, including visual testing, radiography, ultrasonic testing, magnetic particle testing, liquid penetrant testing, and eddy current testing.

What is the job outlook for non-destructive testing professionals?

+The job outlook for non-destructive testing professionals is positive, with the Bureau of Labor Statistics predicting a 10% growth in employment opportunities from 2020 to 2030.