Intro

Unlock a lucrative career in sheet metal worker welding jobs by mastering 7 essential skills. Discover the must-have techniques for welding, metal fabrication, and safety protocols. From blueprint reading to flux cored arc welding, learn the key competencies required for success in this in-demand trade, including MIG, TIG, and AWS certification.

Welding is a crucial aspect of sheet metal work, and possessing the right skills can make all the difference in securing a job in this field. Sheet metal worker welding jobs require a combination of technical knowledge, physical ability, and attention to detail. In this article, we will explore the 7 essential skills required for sheet metal worker welding jobs, providing you with a comprehensive understanding of what it takes to succeed in this field.

Understanding the Basics of Welding

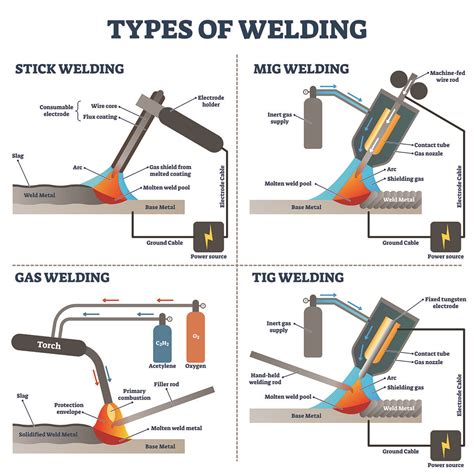

Before diving into the specific skills required for sheet metal worker welding jobs, it's essential to understand the basics of welding. Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. There are several types of welding processes, including Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Gas Tungsten Arc Welding (GTAW).

1. Technical Knowledge of Welding Processes

To be successful in sheet metal worker welding jobs, you need to have a solid understanding of various welding processes, including SMAW, GMAW, and GTAW. This includes knowledge of the equipment, techniques, and safety protocols involved in each process. You should be able to identify the advantages and limitations of each process and choose the most suitable one for a particular job.

2. Familiarity with Welding Equipment and Tools

Sheet metal worker welding jobs require familiarity with a range of equipment and tools, including welding machines, electrodes, shielding gases, and personal protective equipment (PPE). You should be able to operate and maintain welding equipment, as well as troubleshoot common issues that may arise during the welding process.

3. Physical Stamina and Endurance

Welding can be a physically demanding job, requiring long hours of standing, bending, and lifting. You should be physically fit and able to work in a fast-paced environment, often in confined spaces or at heights. Good hand-eye coordination and fine motor skills are also essential for precision welding.

4. Attention to Detail and Quality Control

Sheet metal worker welding jobs require attention to detail and a commitment to quality control. You should be able to inspect your work carefully, identify defects or imperfections, and take corrective action to ensure that the finished product meets the required standards.

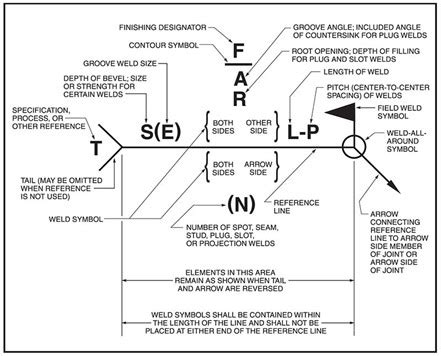

5. Ability to Read and Interpret Blueprints and Diagrams

The ability to read and interpret blueprints and diagrams is critical in sheet metal worker welding jobs. You should be able to understand the specifications and requirements outlined in the blueprint and use this information to guide your welding work.

6. Safety Awareness and Protocol Adherence

Welding can be a hazardous job, and safety awareness is essential to prevent injuries and ensure a safe working environment. You should be familiar with safety protocols, including the use of PPE, ventilation systems, and fire suppression equipment.

7. Continuous Learning and Professional Development

The welding industry is constantly evolving, with new technologies and techniques emerging regularly. To remain competitive in sheet metal worker welding jobs, you should be committed to continuous learning and professional development, staying up-to-date with the latest developments and advancements in the field.

In conclusion, sheet metal worker welding jobs require a unique combination of technical knowledge, physical ability, and attention to detail. By possessing the 7 essential skills outlined in this article, you can increase your chances of success in this field and build a rewarding and challenging career.

Gallery of Sheet Metal Welding

Sheet Metal Welding Image Gallery

What is the most common type of welding used in sheet metal work?

+The most common type of welding used in sheet metal work is Gas Metal Arc Welding (GMAW), also known as MIG welding.

What safety equipment is required for sheet metal welding?

+Safety equipment required for sheet metal welding includes a welding helmet, gloves, safety glasses, and a fire-resistant jacket.

What is the average salary for a sheet metal worker?

+The average salary for a sheet metal worker varies depending on location, experience, and industry, but can range from $40,000 to over $70,000 per year.