Intro

Discover how to test a points condenser with our step-by-step guide. Learn to diagnose and troubleshoot issues with your ignition system, including faulty condensers, using multimeter testing and visual inspections. Ensure your vehicles performance and reliability with this comprehensive tutorial on points condenser testing, ignition system maintenance, and classic car repair.

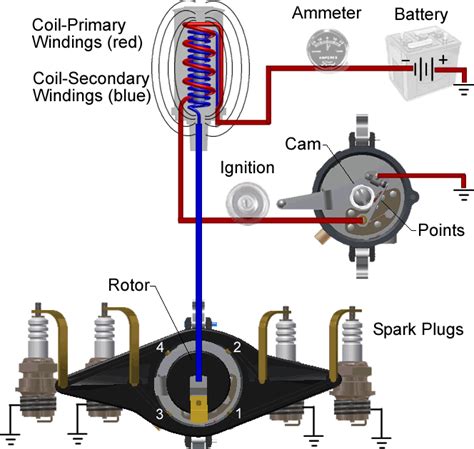

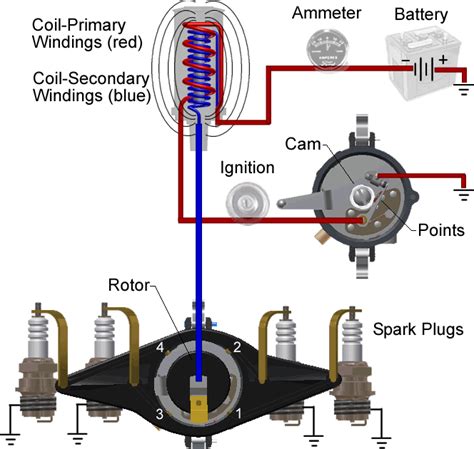

Testing a points condenser is a crucial step in ensuring the proper functioning of a vehicle's ignition system. The points condenser, also known as a capacitor, plays a vital role in storing and releasing electrical energy to the spark plugs. In this article, we will guide you through the process of testing a points condenser, helping you to identify any potential issues and get your vehicle running smoothly.

The importance of a points condenser cannot be overstated. It helps to regulate the flow of electrical energy to the spark plugs, ensuring that the engine runs efficiently and effectively. A faulty points condenser can cause a range of problems, including misfires, rough idling, and decreased engine performance.

Understanding the Points Condenser

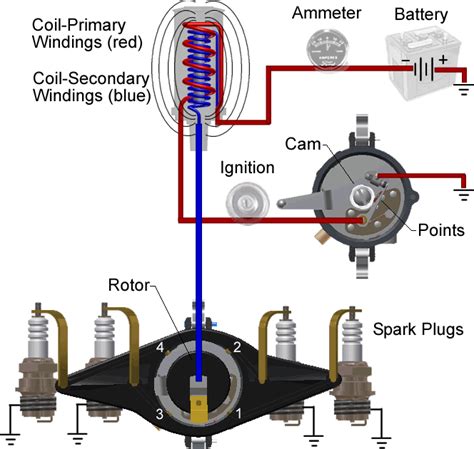

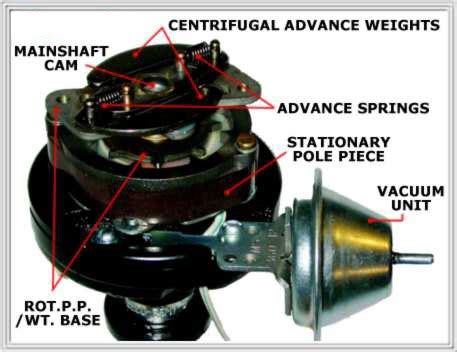

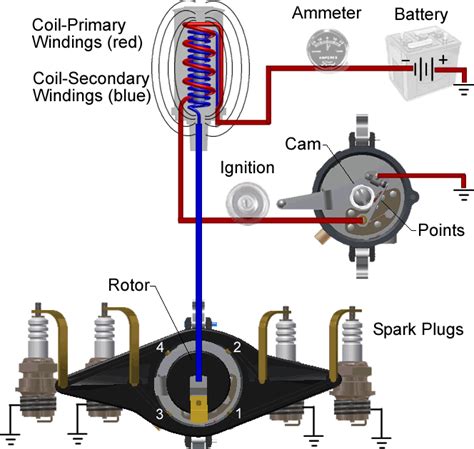

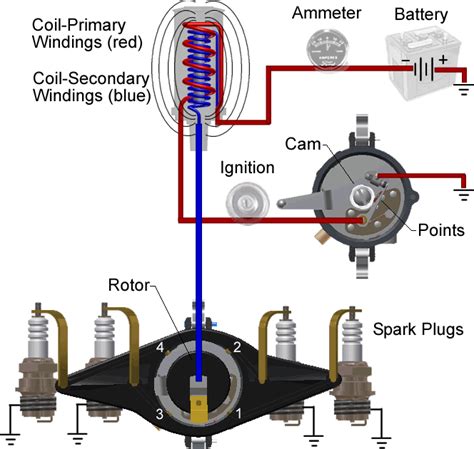

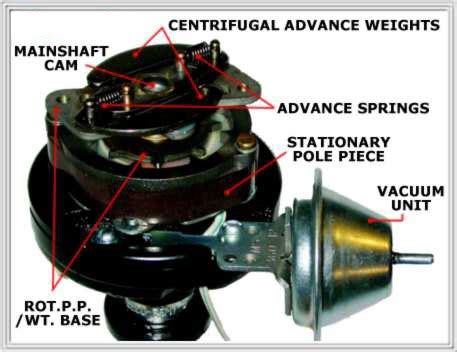

Before we dive into the testing process, it's essential to understand the basics of a points condenser. The points condenser is a type of capacitor that stores electrical energy and releases it to the spark plugs. It is typically located inside the distributor cap and is connected to the points (also known as the contact breaker).

Components of a Points Condenser

A points condenser consists of two main components: the capacitor and the points. The capacitor stores electrical energy, while the points (or contact breaker) switch the energy on and off.

Step-by-Step Guide to Testing a Points Condenser

Testing a points condenser is a relatively straightforward process that requires a few basic tools. Here's a step-by-step guide to help you get started:

Step 1: Gather Your Tools and Materials

- A multimeter (set to ohms function)

- A spark tester

- A points condenser testing adapter (optional)

- A replacement points condenser (if necessary)

Step 2: Remove the Distributor Cap

- Locate the distributor cap and remove it to access the points condenser.

- Take note of the spark plug wire locations and mark them for reference.

Step 3: Identify the Points Condenser

- Locate the points condenser and take note of its condition.

- Check for any signs of wear, damage, or corrosion.

Step 4: Test the Points Condenser

- Set your multimeter to the ohms function and connect the leads to the points condenser.

- Take a reading of the resistance (ohms) and compare it to the manufacturer's specifications.

- If the reading is outside of the specified range, the points condenser may be faulty.

Step 5: Test the Spark

- Use a spark tester to check the spark output.

- If the spark is weak or absent, it may indicate a faulty points condenser.

Step 6: Replace the Points Condenser (If Necessary)

- If the points condenser is faulty, replace it with a new one.

- Make sure to follow the manufacturer's instructions for replacement.

Common Issues with Points Condensers

- Weak or absent spark

- Misfires

- Rough idling

- Decreased engine performance

Prevention and Maintenance

- Regularly check the points condenser for signs of wear or damage.

- Replace the points condenser every 10,000 to 20,000 miles.

- Keep the distributor cap and spark plug wires clean and dry.

Points Condenser Image Gallery

What is the purpose of a points condenser?

+The points condenser is a type of capacitor that stores electrical energy and releases it to the spark plugs, helping to regulate the flow of electrical energy to the engine.

What are the symptoms of a faulty points condenser?

+Common symptoms of a faulty points condenser include weak or absent spark, misfires, rough idling, and decreased engine performance.

How often should I replace the points condenser?

+It's recommended to replace the points condenser every 10,000 to 20,000 miles, or as specified by the manufacturer.

We hope this article has provided you with a comprehensive guide to testing a points condenser. Remember to always follow proper safety procedures when working with electrical systems, and consult a professional mechanic if you're unsure about any aspect of the process.