Intro

Discover the crucial role of welding in the army, from repairing equipment to building infrastructure. Learn about the 5 ways welding is used in the military, including metal fabrication, vehicle maintenance, and more. Explore the techniques and applications used by military personnel, highlighting the importance of welding in supporting army operations and personnel safety.

Welding is a crucial skill in the Army, playing a vital role in various military operations and equipment maintenance. The Army relies heavily on welding to ensure that its vehicles, equipment, and infrastructure are in good working condition. In this article, we'll explore five ways welding is used in the Army.

1. Vehicle Maintenance and Repair

The Army has a vast fleet of vehicles, including tanks, trucks, and armored personnel carriers. These vehicles are subject to heavy wear and tear, and welding is essential for maintaining and repairing them. Army welders use various techniques, such as shielded metal arc welding (SMAW) and gas metal arc welding (GMAW), to repair damaged vehicle parts, including armor plating, engine components, and suspension systems.

Types of Vehicle Repairs

- Repairing damaged armor plating on tanks and armored vehicles

- Rebuilding engine components, such as engine blocks and cylinder heads

- Repairing suspension systems, including shock absorbers and springs

2. Equipment Fabrication and Modification

The Army often requires custom-made equipment to support its operations. Welding is used to fabricate and modify equipment, such as machine gun mounts, ammunition racks, and storage containers. Army welders use computer-aided design (CAD) software to create precise designs and then use welding techniques, such as gas tungsten arc welding (GTAW) and submerged arc welding (SAW), to fabricate the equipment.

Examples of Equipment Fabrication

- Fabricating machine gun mounts for armored vehicles

- Building ammunition racks for artillery systems

- Creating storage containers for military supplies

3. Infrastructure Development and Repair

The Army often operates in remote areas, where infrastructure is limited or non-existent. Welding is used to develop and repair infrastructure, such as bridges, roads, and buildings. Army welders use techniques, such as flux cored arc welding (FCAW) and shielded metal arc welding (SMAW), to construct and repair infrastructure.

Types of Infrastructure Development

- Building bridges for river crossings

- Constructing roads and highways

- Repairing damaged buildings and structures

4. Demolition and Explosive Ordnance Disposal

Welding is also used in demolition and explosive ordnance disposal (EOD) operations. Army welders use specialized techniques, such as thermal cutting and welding, to safely dispose of explosive materials and demolish structures. This requires a high level of skill and precision to avoid accidents and ensure safety.

Examples of Demolition and EOD Operations

- Disposing of explosive materials, such as bombs and grenades

- Demolishing structures, such as buildings and bridges

5. Research and Development

The Army is constantly seeking to improve its equipment and operations. Welding plays a crucial role in research and development, as Army welders work with scientists and engineers to develop new materials and technologies. This includes testing and evaluating new welding techniques and materials, such as advanced alloys and composites.

Examples of R&D Projects

- Developing new materials for armor plating

- Testing and evaluating advanced welding techniques

- Creating prototype equipment for future operations

Army Welding Techniques Image Gallery

What is the most common welding technique used in the Army?

+The most common welding technique used in the Army is shielded metal arc welding (SMAW).

What type of equipment do Army welders use?

+Army welders use a variety of equipment, including welding machines, helmets, gloves, and safety glasses.

How do Army welders stay safe while welding?

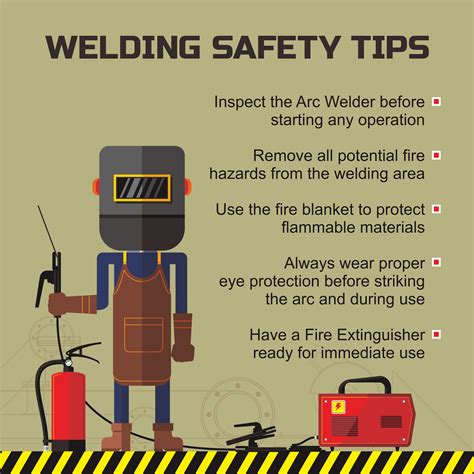

+Army welders follow strict safety protocols, including wearing protective gear, using proper ventilation, and following established welding procedures.

We hope this article has provided a comprehensive overview of the various ways welding is used in the Army. From vehicle maintenance and repair to research and development, welding plays a vital role in supporting military operations. If you have any questions or would like to learn more about Army welding techniques, please feel free to comment below or share this article with others.