Intro

Discover how industrial engineers drive business efficiency through innovative strategies. Learn the 7 ways they optimize processes, reduce waste, and improve productivity. From lean manufacturing to data analytics, uncover the techniques that boost profitability and competitiveness in todays fast-paced industrial landscape.

In today's fast-paced and highly competitive business landscape, efficiency is key to success. One way companies can achieve this is by leveraging the expertise of industrial engineers. These professionals are trained to analyze and optimize complex systems, processes, and workflows, helping organizations streamline their operations and improve overall performance. In this article, we will explore seven ways industrial engineers can boost business efficiency.

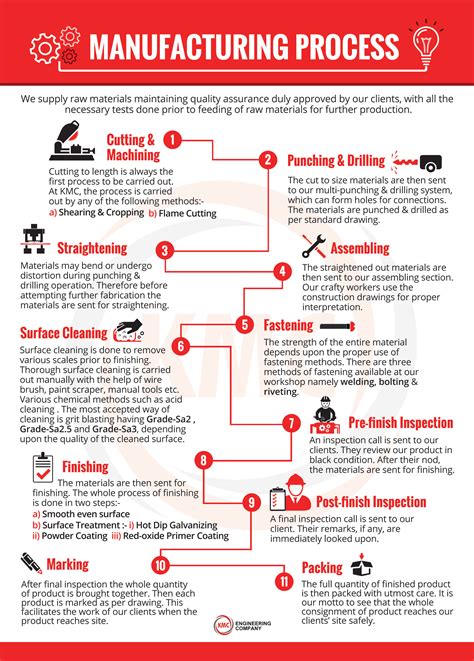

1. Process Optimization

Industrial engineers use various techniques, such as lean manufacturing and Six Sigma, to identify and eliminate inefficiencies in business processes. By analyzing data and workflows, they can pinpoint areas of waste and develop strategies to reduce or eliminate them. This can lead to significant cost savings, improved productivity, and enhanced customer satisfaction.

Benefits of Process Optimization

- Reduced waste and variability

- Improved quality and reliability

- Increased productivity and efficiency

- Enhanced customer satisfaction

2. Supply Chain Management

Industrial engineers play a crucial role in designing and optimizing supply chains. By analyzing the flow of goods, services, and information, they can identify bottlenecks and areas for improvement. This can lead to reduced lead times, lower inventory costs, and improved delivery performance.

Benefits of Supply Chain Management

- Reduced lead times and inventory costs

- Improved delivery performance and customer satisfaction

- Increased flexibility and responsiveness to changing market conditions

- Enhanced collaboration and communication among suppliers, manufacturers, and customers

3. Quality Control and Assurance

Industrial engineers are responsible for ensuring that products and services meet customer requirements and specifications. By developing and implementing quality control and assurance processes, they can identify and correct defects, reducing the risk of errors and improving overall quality.

Benefits of Quality Control and Assurance

- Improved product quality and reliability

- Reduced risk of errors and defects

- Enhanced customer satisfaction and loyalty

- Increased efficiency and productivity

4. Ergonomics and Workplace Design

Industrial engineers design and optimize workplaces to improve employee safety, comfort, and productivity. By analyzing workflows and tasks, they can identify opportunities to reduce strain and improve working conditions, leading to enhanced employee well-being and job satisfaction.

Benefits of Ergonomics and Workplace Design

- Improved employee safety and well-being

- Enhanced productivity and job satisfaction

- Reduced risk of injuries and illnesses

- Increased employee retention and reduced turnover

5. Project Management

Industrial engineers are skilled project managers, able to plan, execute, and deliver projects on time, within budget, and to the required quality standards. By using project management tools and techniques, they can ensure that projects are completed efficiently and effectively, meeting stakeholder expectations.

Benefits of Project Management

- Improved project delivery and timelines

- Enhanced quality and customer satisfaction

- Reduced project costs and improved budget management

- Increased stakeholder confidence and trust

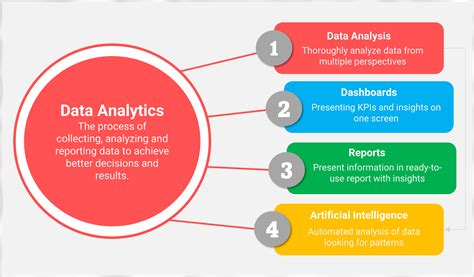

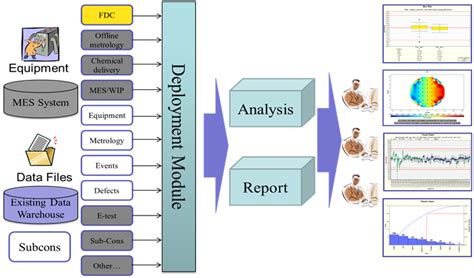

6. Data Analysis and Decision-Making

Industrial engineers use data analysis and statistical techniques to inform decision-making and drive business improvement. By analyzing data and identifying trends, they can develop insights that support strategic business decisions, driving growth and improvement.

Benefits of Data Analysis and Decision-Making

- Improved decision-making and strategic planning

- Enhanced business intelligence and insights

- Increased efficiency and productivity

- Reduced risk and uncertainty

7. Innovation and Creativity

Industrial engineers are trained to think creatively and develop innovative solutions to complex problems. By encouraging experimentation and risk-taking, they can drive business growth and improvement, identifying new opportunities and developing innovative products and services.

Benefits of Innovation and Creativity

- Improved business growth and competitiveness

- Enhanced innovation and creativity

- Increased efficiency and productivity

- Reduced risk and uncertainty

Industrial Engineering Image Gallery

What is industrial engineering?

+Industrial engineering is a branch of engineering that deals with the optimization of complex systems, processes, and workflows.

What are the benefits of industrial engineering?

+The benefits of industrial engineering include improved efficiency, productivity, and quality, as well as reduced costs and enhanced customer satisfaction.

How can industrial engineers contribute to business growth?

+Industrial engineers can contribute to business growth by developing innovative solutions, improving processes and workflows, and driving strategic decision-making.

We hope this article has provided valuable insights into the role of industrial engineers in boosting business efficiency. By leveraging their expertise in process optimization, supply chain management, quality control, and innovation, companies can drive growth, improvement, and success. If you have any questions or would like to learn more about industrial engineering, please feel free to comment below or share this article with your network.