Intro

Discover the meaning of MIG in welding and unlock the secrets of this popular process. Learn what MIG stands for, its applications, and benefits in metal fabrication. Explore the differences between MIG and other welding techniques, such as TIG and ARC welding. Master the basics of MIG welding and elevate your fabrication skills.

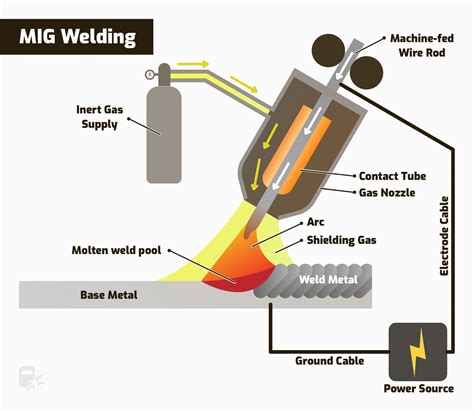

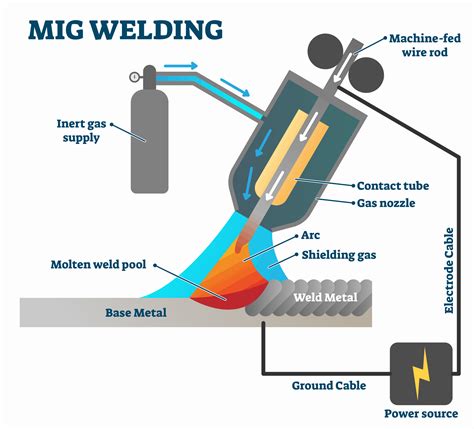

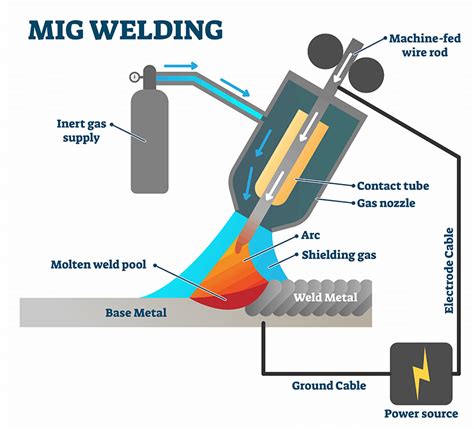

MIG stands for Metal Inert Gas, which is a type of welding process that uses a continuous wire electrode and an inert gas to shield the arc. It is also known as Gas Metal Arc Welding (GMAW). The MIG welding process is widely used in various industries, including automotive, construction, and manufacturing, due to its high speed, efficiency, and versatility.

The MIG welding process was first developed in the 1940s and has since become a popular choice for welding a variety of metals, including steel, aluminum, and stainless steel. The process involves feeding a continuous wire electrode through a welding gun, which is connected to a power source and a gas tank. The wire electrode is heated by an electric arc, which melts the metal and creates a strong bond.

How MIG Welding Works

The MIG welding process works as follows:

- The wire electrode is fed through the welding gun and into the weld pool.

- The wire electrode is heated by an electric arc, which melts the metal and creates a strong bond.

- The inert gas, usually argon or helium, is released through the welding gun and surrounds the weld pool.

- The gas shield protects the weld pool from atmospheric gases, such as oxygen and nitrogen, which can cause porosity and other defects.

- The wire electrode is continuously fed through the welding gun, allowing for a smooth and consistent weld.

Benefits of MIG Welding

MIG welding offers several benefits, including:

- High speed: MIG welding is a fast process that can produce high-quality welds quickly.

- Efficiency: MIG welding uses a continuous wire electrode, which reduces waste and saves time.

- Versatility: MIG welding can be used on a variety of metals, including steel, aluminum, and stainless steel.

- Easy to learn: MIG welding is a relatively easy process to learn, making it a great choice for beginners.

Types of MIG Welding

There are several types of MIG welding, including:

- Short-circuit MIG welding: This process uses a short circuit to create a weld pool.

- Pulsed MIG welding: This process uses a pulsed current to create a weld pool.

- Spray MIG welding: This process uses a high-speed wire electrode to create a weld pool.

- Flux-cored MIG welding: This process uses a flux-cored wire electrode to create a weld pool.

MIG Welding Equipment

MIG welding equipment includes:

- Welding gun: This is the handheld device that feeds the wire electrode and releases the inert gas.

- Power source: This is the device that provides the electrical power for the welding process.

- Gas tank: This is the container that holds the inert gas.

- Wire feeder: This is the device that feeds the wire electrode through the welding gun.

MIG Welding Safety

MIG welding safety is important to prevent injuries and ensure a safe working environment. Some safety precautions include:

- Wearing protective gear, such as a welding helmet and gloves.

- Ensuring good ventilation to prevent inhaling fumes.

- Keeping loose clothing and long hair tied back.

- Avoiding electrical shock by ensuring the power source is turned off when not in use.

MIG Welding Applications

MIG welding is widely used in various industries, including:

- Automotive: MIG welding is used to manufacture car bodies and repair damaged vehicles.

- Construction: MIG welding is used to build and repair buildings, bridges, and other structures.

- Manufacturing: MIG welding is used to manufacture machinery, equipment, and other products.

- Aerospace: MIG welding is used to manufacture aircraft and spacecraft.

MIG Welding Image Gallery

What is MIG welding?

+MIG welding is a type of welding process that uses a continuous wire electrode and an inert gas to shield the arc.

What are the benefits of MIG welding?

+MIG welding offers several benefits, including high speed, efficiency, versatility, and ease of use.

What are the different types of MIG welding?

+There are several types of MIG welding, including short-circuit MIG welding, pulsed MIG welding, spray MIG welding, and flux-cored MIG welding.

What are the safety precautions for MIG welding?

+MIG welding safety precautions include wearing protective gear, ensuring good ventilation, keeping loose clothing and long hair tied back, and avoiding electrical shock.

What are the applications of MIG welding?

+MIG welding is widely used in various industries, including automotive, construction, manufacturing, and aerospace.

In conclusion, MIG welding is a popular and versatile welding process that offers several benefits, including high speed, efficiency, and ease of use. By understanding the basics of MIG welding, including its process, equipment, and safety precautions, you can unlock its full potential and achieve high-quality welds in a variety of applications.