Intro

Unlock the secrets of afterburners! Discover how this innovative technology works, increasing an engines thrust and efficiency. Learn about the afterburners components, operating principles, and applications in aerospace and military industries. Explore the benefits and challenges of afterburner systems, and gain insight into their role in modern aviation and rocket propulsion.

The afterburner, a crucial component in the operation of high-performance jet engines, particularly those used in military aircraft. Its primary function is to significantly increase the engine's thrust output, albeit at the cost of increased fuel consumption. This boost in thrust is especially useful during takeoff, combat maneuvers, or when the aircraft is required to operate at high altitudes.

To understand how an afterburner works, we must delve into the fundamental principles of jet engine operation and the additional mechanisms employed by the afterburner to enhance thrust.

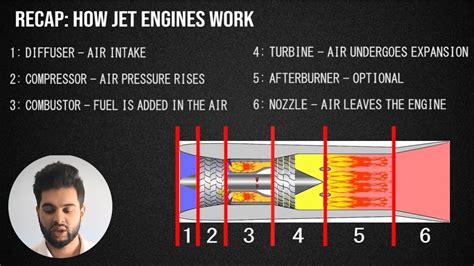

Basic Principles of Jet Engine Operation

Jet engines operate on the principle of conserving momentum. Air is drawn into the engine, compressed, mixed with fuel, and then ignited in the combustion chamber. The hot gases produced by this combustion process expand rapidly through the nozzle at the rear of the engine, generating a high-speed exhaust. According to Newton's third law of motion, the forward motion of the aircraft is a direct result of the backward expulsion of these exhaust gases.

Components of a Jet Engine

- Compressor: This component compresses the air, which is then mixed with fuel.

- Combustion Chamber (Combustor): The mixture of air and fuel is ignited here.

- Turbine: The energy from the hot gases is extracted here to drive the compressor and other engine accessories.

- Nozzle: The final component where the exhaust gases accelerate to generate thrust.

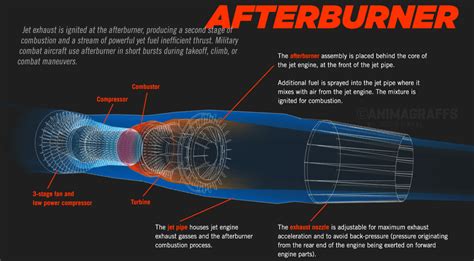

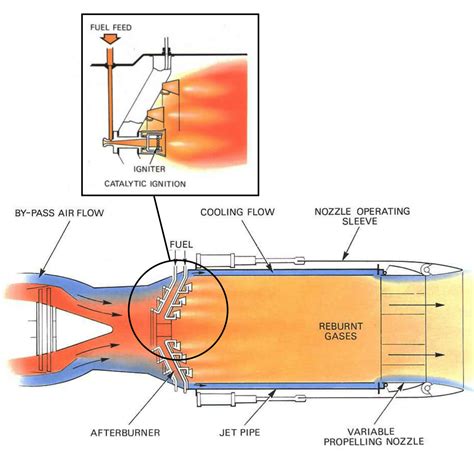

The Afterburner Mechanism

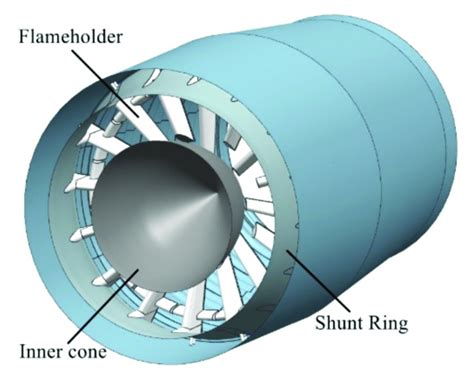

An afterburner is essentially a secondary combustion chamber located behind the turbine in a jet engine. When activated, it injects additional fuel into the hot exhaust gases produced by the turbine. This fuel is then ignited, causing the gases to expand further, which in turn accelerates the exhaust gases to higher velocities. This increase in exhaust velocity directly translates into a significant increase in thrust, as per the principle of conservation of momentum.

Key Features of an Afterburner

- Fuel Injection: Afterburners have a separate fuel system for injecting fuel into the exhaust nozzle.

- Ignition System: A reliable ignition system is necessary to ignite the fuel in the afterburner.

- Increased Thrust: The primary benefit of an afterburner, achievable at the cost of higher fuel consumption.

Operation Modes of an Afterburner

Afterburners can operate in different modes, depending on the specific engine design and the requirements of the flight regime.

- Dry Mode: The engine operates without the afterburner, relying solely on the primary combustion process for thrust generation.

- Wet Mode (Afterburner): Fuel is injected into the afterburner, and the additional combustion process significantly increases the thrust output.

Advantages and Disadvantages

Advantages:

- Significant increase in thrust output, useful for short bursts of high speed or during emergencies.

- Enables military aircraft to achieve high speeds necessary for combat.

Disadvantages:

- High fuel consumption, leading to reduced range and endurance.

- Increased wear and tear on the engine due to higher operating temperatures.

Modern Developments in Afterburner Technology

Research and development in afterburner technology focus on improving efficiency, reducing fuel consumption, and minimizing environmental impact. Advances in materials science have led to the development of more durable components that can withstand the high temperatures associated with afterburner operation.

Future Directions

- High-Temperature Materials: Research into materials that can sustain even higher temperatures, potentially leading to more efficient afterburner operation.

- Alternative Fuels: Exploration of alternative fuels that could offer better efficiency and reduced environmental impact.

Conclusion

The afterburner is a critical component in high-performance jet engines, especially in military aircraft, where the need for rapid acceleration and high-speed maneuverability is paramount. Understanding the operation and principles behind afterburners provides insight into the complex engineering that underpins modern jet engines.Afterburner Image Gallery

What is the primary function of an afterburner in a jet engine?

+The primary function of an afterburner is to increase the thrust output of a jet engine by injecting additional fuel into the hot exhaust gases produced by the turbine and igniting it, thus accelerating the exhaust gases to higher velocities.

What are the advantages of using an afterburner?

+The significant increase in thrust output allows for faster acceleration and higher speeds, making it particularly useful in military aircraft for combat maneuvers and in civilian aircraft for overcoming obstacles during takeoff.

What are the main disadvantages of afterburners?

+The primary disadvantages include high fuel consumption, reduced range and endurance, and increased wear and tear on the engine due to higher operating temperatures.