Intro

Unlock the world of industrial engineering! Discover what an industrial engineer does, their roles, and responsibilities. Learn about the fields intersection with operations research, systems engineering, and management science. Find out how industrial engineers optimize processes, improve efficiency, and increase productivity in various industries, from manufacturing to healthcare.

Industrial engineers are professionals who specialize in designing, optimizing, and improving systems, processes, and facilities to increase efficiency, productivity, and quality. They use a combination of technical knowledge, business acumen, and analytical skills to identify and solve problems, often working closely with other engineers, managers, and stakeholders. Industrial engineers are versatile and can work in various industries, including manufacturing, healthcare, logistics, and more.

Industrial engineers are essential in today's fast-paced, globalized world, where companies need to stay competitive and adapt to changing market conditions. By applying principles from engineering, business, and social sciences, industrial engineers can help organizations reduce costs, improve customer satisfaction, and enhance overall performance.

Key Responsibilities of Industrial Engineers

Industrial engineers have a wide range of responsibilities, which may vary depending on the industry, company, and specific role. Some common tasks and responsibilities include:

- Analyzing and optimizing systems, processes, and facilities to improve efficiency and productivity

- Designing and implementing new systems, processes, and facilities

- Conducting time and motion studies to identify areas for improvement

- Developing and implementing quality control procedures

- Managing and supervising teams of engineers, technicians, and other staff

- Coordinating with other departments, such as manufacturing, logistics, and sales

- Developing and managing budgets and resource allocation

- Conducting risk assessments and implementing safety protocols

Skills and Qualifications Required

To become a successful industrial engineer, one should possess a combination of technical, business, and soft skills. Some essential skills and qualifications include:

- Bachelor's or master's degree in industrial engineering or a related field

- Strong analytical and problem-solving skills

- Excellent communication and interpersonal skills

- Ability to work in a team environment and lead others

- Strong business acumen and understanding of financial principles

- Familiarity with industry-specific software and technologies

- Certification in industrial engineering or a related field (optional)

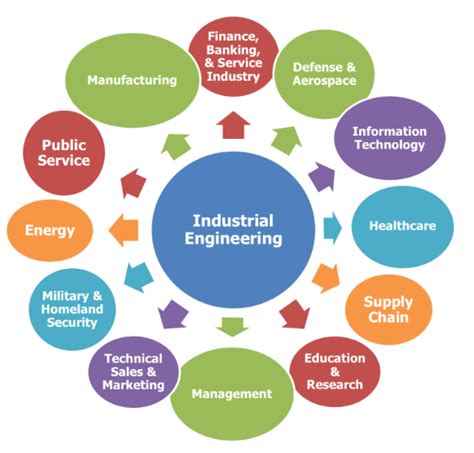

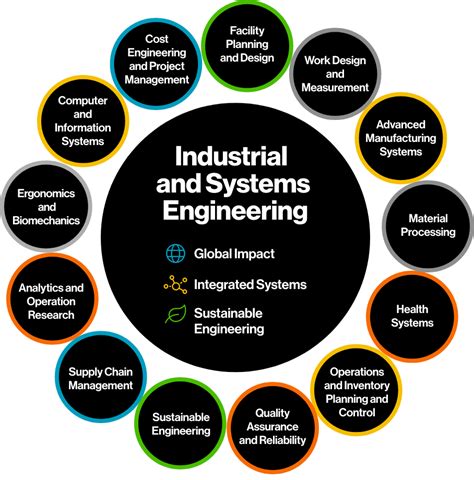

Types of Industrial Engineers

Industrial engineers can specialize in various areas, including:

- Manufacturing engineering: focuses on designing and optimizing manufacturing systems and processes

- Quality engineering: focuses on developing and implementing quality control procedures

- Logistics engineering: focuses on designing and optimizing logistics and supply chain systems

- Human factors engineering: focuses on designing systems and processes that are safe and efficient for workers

- Systems engineering: focuses on designing and optimizing complex systems and processes

Benefits of Being an Industrial Engineer

A career as an industrial engineer can be highly rewarding, with numerous benefits, including:

- Competitive salary and benefits

- Opportunities for advancement and professional growth

- Variety of work and opportunities to work in different industries

- Sense of accomplishment and satisfaction from improving processes and systems

- Opportunities to work on exciting and challenging projects

- Collaborative and dynamic work environment

Challenges Faced by Industrial Engineers

Industrial engineers may face various challenges, including:

- Staying up-to-date with technological advancements and industry trends

- Managing competing priorities and tight deadlines

- Communicating effectively with stakeholders and team members

- Balancing technical and business considerations

- Dealing with complex and dynamic systems

- Managing and mitigating risks and uncertainties

Real-World Applications of Industrial Engineering

Industrial engineers have a significant impact on various industries and aspects of our lives. Some examples of real-world applications include:

- Improving manufacturing efficiency and productivity

- Optimizing logistics and supply chain systems

- Enhancing customer experience and satisfaction

- Reducing costs and improving profitability

- Developing and implementing quality control procedures

- Designing and optimizing healthcare systems and facilities

Conclusion

In conclusion, industrial engineers play a vital role in designing, optimizing, and improving systems, processes, and facilities to increase efficiency, productivity, and quality. With a combination of technical knowledge, business acumen, and analytical skills, industrial engineers can help organizations stay competitive and adapt to changing market conditions. As technology continues to advance and industries evolve, the demand for skilled industrial engineers will only continue to grow.

Call to Action

If you're interested in learning more about industrial engineering or pursuing a career in this field, we encourage you to explore further. Research industrial engineering programs, reach out to professionals in the field, and consider gaining practical experience through internships or volunteer work.

Share Your Thoughts

We'd love to hear from you! Share your thoughts on industrial engineering, its applications, and its benefits. What do you think are the most significant challenges facing industrial engineers today? How do you think industrial engineering can impact society and the environment?

Industrial Engineering Image Gallery

What is industrial engineering?

+Industrial engineering is the application of engineering principles and methods to design, optimize, and improve systems, processes, and facilities to increase efficiency, productivity, and quality.

What are the key responsibilities of industrial engineers?

+Industrial engineers are responsible for analyzing and optimizing systems, processes, and facilities, designing and implementing new systems, and managing and supervising teams.

What skills and qualifications are required to become an industrial engineer?

+Industrial engineers typically require a bachelor's or master's degree in industrial engineering or a related field, strong analytical and problem-solving skills, and excellent communication and interpersonal skills.