Intro

Discover the strength and versatility of Cold Steel, a high-carbon content material prized for its durability and affordability. Learn about its unique characteristics, manufacturing process, and diverse applications in knives, swords, axes, and more. Explore the benefits and limitations of Cold Steel and how it compares to other materials.

The world of steel is vast and diverse, with various types of steel offering unique properties and uses. Among these, cold steel stands out for its distinct characteristics and applications. But what exactly is cold steel, and what are its uses? In this article, we'll delve into the world of cold steel, exploring its definition, benefits, and applications.

What is Cold Steel?

Cold steel refers to a type of steel that has been processed at room temperature, without the use of heat. This processing method allows the steel to retain its strength and durability, while also making it more resistant to corrosion and wear. Cold steel is often compared to hot steel, which is processed at high temperatures to achieve specific properties.

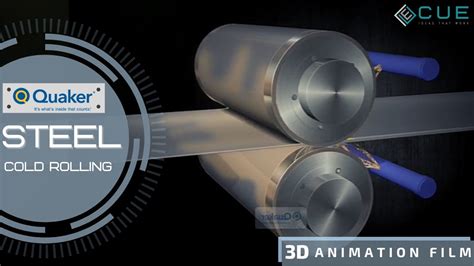

How is Cold Steel Made?

The production of cold steel involves several steps, including:

- Selection of raw materials: The process begins with the selection of high-quality raw materials, such as iron ore and coal.

- Melting and casting: The raw materials are melted and cast into a desired shape.

- Cold rolling: The steel is then cold rolled, which involves passing the steel through a series of rollers at room temperature. This process helps to shape the steel and achieve the desired thickness.

- Annealing: The steel is then annealed, which involves heating it to a specific temperature and then cooling it slowly. This process helps to relieve any stresses in the steel.

Benefits of Cold Steel

Cold steel offers several benefits, including:

- Increased strength: Cold steel is stronger and more durable than hot steel, making it ideal for applications where high strength is required.

- Improved corrosion resistance: Cold steel is more resistant to corrosion and wear, making it suitable for use in harsh environments.

- Better dimensional stability: Cold steel has better dimensional stability, which means it retains its shape and size even when exposed to extreme temperatures.

- Enhanced aesthetic appeal: Cold steel has a smooth, shiny finish that makes it ideal for decorative applications.

Uses of Cold Steel

Cold steel has a wide range of applications, including:

- Automotive industry: Cold steel is used in the production of car parts, such as engine components and body panels.

- Construction industry: Cold steel is used in building construction, particularly in the production of beams and columns.

- Aerospace industry: Cold steel is used in the production of aircraft parts, such as engine components and structural components.

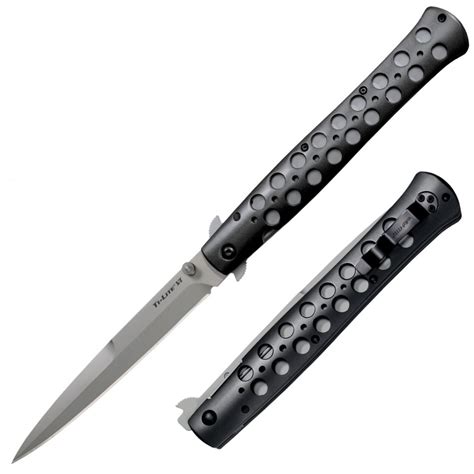

- Cutlery industry: Cold steel is used in the production of high-quality knives and other cutlery.

Types of Cold Steel

There are several types of cold steel, including:

- Cold rolled steel: This type of steel is produced by cold rolling hot steel.

- Cold drawn steel: This type of steel is produced by drawing hot steel through a die.

- Cold forged steel: This type of steel is produced by forging hot steel at room temperature.

Applications of Cold Steel in Various Industries

Cold steel has a wide range of applications in various industries, including:

- Automotive industry: Cold steel is used in the production of car parts, such as engine components and body panels.

- Construction industry: Cold steel is used in building construction, particularly in the production of beams and columns.

- Aerospace industry: Cold steel is used in the production of aircraft parts, such as engine components and structural components.

- Cutlery industry: Cold steel is used in the production of high-quality knives and other cutlery.

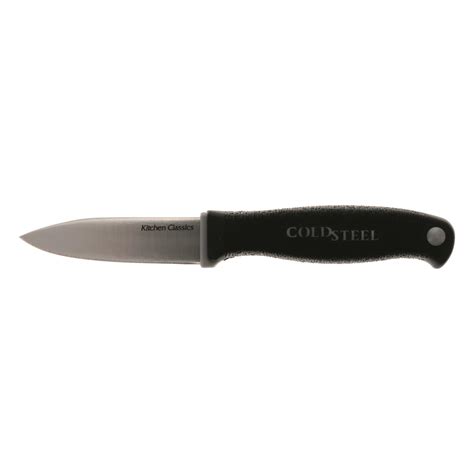

Gallery of Cold Steel Images

Cold Steel Image Gallery

Frequently Asked Questions

What is cold steel?

+Cold steel is a type of steel that has been processed at room temperature, without the use of heat.

What are the benefits of cold steel?

+Cold steel offers several benefits, including increased strength, improved corrosion resistance, better dimensional stability, and enhanced aesthetic appeal.

What are the uses of cold steel?

+Cold steel has a wide range of applications, including the automotive industry, construction industry, aerospace industry, and cutlery industry.

Conclusion

Cold steel is a versatile and valuable material that offers a range of benefits and applications. Its unique properties make it an ideal choice for various industries, from automotive to aerospace. Whether you're a manufacturer or a consumer, understanding the benefits and uses of cold steel can help you make informed decisions about your steel needs. We hope this article has provided you with a comprehensive overview of cold steel and its many uses. If you have any further questions or comments, please don't hesitate to contact us.