Intro

Discover the epic story of Building the Chunnel, a marvel of modern engineering that connected England and France. Learn about the intricate tunnel design, innovative construction techniques, and immense challenges overcome during this monumental project, a true feat of human ingenuity and perseverance.

The Channel Tunnel, commonly known as the Chunnel, is a 50-kilometer undersea tunnel that connects England and France. The tunnel, which was completed in 1994, is considered one of the most impressive engineering feats of the 20th century. The construction of the Chunnel required innovative solutions to complex engineering problems, and its completion has had a significant impact on transportation and commerce between the two countries.

The idea of building a tunnel under the English Channel dates back to the early 19th century. However, it wasn't until the 1970s that the project gained momentum. The British and French governments agreed to build the tunnel, and a consortium of contractors, including TransManche Link (TML), was formed to carry out the project.

Planning and Design

The planning and design phase of the Chunnel project was a complex and challenging process. The tunnel had to be designed to withstand the harsh conditions of the English Channel, including strong currents and high water pressure. The engineers also had to ensure that the tunnel was safe for passengers and freight.

The Chunnel was designed as a two-tube tunnel, with one tube for each direction of travel. The tunnel was constructed using the "cut-and-cover" method, where a trench was dug in the seabed and then covered with a concrete lining. The tunnel was also equipped with a sophisticated ventilation system to maintain a safe and comfortable environment for passengers.

Geological Challenges

One of the biggest challenges faced by the engineers was the geological condition of the seabed. The English Channel is a complex geological region, with a mix of chalk, clay, and sand. The engineers had to develop specialized drilling equipment to excavate the tunnel through the hard chalk and clay.

The tunnel also had to be designed to withstand the risk of earthquakes and seismic activity. The engineers used advanced computer simulations to model the behavior of the tunnel under different seismic scenarios.

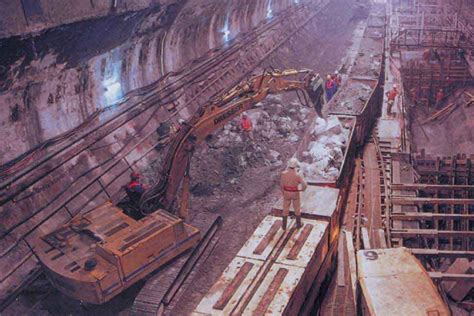

Construction

The construction of the Chunnel began in 1986 and took over eight years to complete. The project required the collaboration of thousands of workers from both Britain and France. The workers faced challenging conditions, including high water pressure, strong currents, and the risk of explosion.

The tunnel was constructed using a combination of drilling and blasting techniques. The engineers used advanced drilling equipment to excavate the tunnel, and then used blasting to break up the rock. The tunnel was also lined with a thick layer of concrete to provide additional strength and stability.

Environmental Impact

The construction of the Chunnel had a significant environmental impact. The project required the excavation of millions of tons of rock and soil, which was then disposed of at sea. The engineers also had to take steps to minimize the impact of the tunnel on marine life.

The Chunnel was designed to be environmentally friendly, with a sophisticated system for monitoring and controlling water quality. The tunnel was also equipped with a system for removing waste and debris.

Benefits of the Chunnel

The Chunnel has had a significant impact on transportation and commerce between Britain and France. The tunnel has reduced travel times between the two countries, making it easier for people and goods to move between them.

The Chunnel has also had a significant economic impact. The tunnel has increased trade between Britain and France, and has helped to boost economic growth in both countries.

Technical Specifications

Here are some technical specifications of the Chunnel:

- Length: 50 kilometers

- Diameter: 7.6 meters

- Depth: up to 40 meters

- Speed: up to 320 kilometers per hour

- Capacity: up to 400 trains per day

Gallery of Chunnel Images

Chunnel Image Gallery

Frequently Asked Questions

How long did it take to build the Chunnel?

+The Chunnel took over eight years to build, from 1986 to 1994.

How deep is the Chunnel?

+The Chunnel is up to 40 meters deep in some areas.

How many trains can the Chunnel handle per day?

+The Chunnel can handle up to 400 trains per day.

Is the Chunnel safe?

+Yes, the Chunnel is designed with safety in mind, with multiple safety features and emergency response plans in place.

How much did the Chunnel cost to build?

+The Chunnel cost around £9.5 billion to build.

In conclusion, the Chunnel is an incredible feat of modern engineering that has revolutionized transportation between Britain and France. Its construction was a complex and challenging process, but the end result is a safe, efficient, and environmentally friendly way to travel between the two countries.