Intro

Discover the pivotal role of industrial engineers in optimizing processes and systems. Explore the 7 key responsibilities of industrial engineers, including process improvement, ergonomics, quality control, and supply chain management. Learn how they apply engineering principles to increase efficiency, reduce costs, and enhance productivity in various industries.

Industrial engineers play a crucial role in optimizing the efficiency and productivity of various industries, including manufacturing, healthcare, and logistics. Their primary goal is to design, improve, and install systems, processes, and facilities to reduce costs, increase efficiency, and enhance the quality of products and services. Here are seven key responsibilities of industrial engineers:

Designing and Implementing Efficient Systems

Industrial engineers are responsible for designing and implementing efficient systems, processes, and facilities. They use computer simulations, statistical models, and other tools to analyze and optimize system performance. This involves identifying bottlenecks, streamlining workflows, and implementing new technologies to improve productivity and reduce costs.

Key Activities:

- Conducting needs assessments to identify areas for improvement

- Developing and testing new systems and processes

- Implementing and evaluating the effectiveness of new systems and processes

- Collaborating with cross-functional teams to ensure successful implementation

Improving Quality and Reducing Waste

Industrial engineers are responsible for improving the quality of products and services while reducing waste and minimizing environmental impact. They use techniques such as Six Sigma, lean manufacturing, and total quality management to identify and eliminate defects, variations, and inefficiencies.

Key Activities:

- Conducting quality control audits to identify areas for improvement

- Developing and implementing quality control procedures

- Analyzing data to identify trends and opportunities for improvement

- Collaborating with suppliers and contractors to ensure quality standards are met

Managing Supply Chains and Logistics

Industrial engineers are responsible for managing supply chains and logistics to ensure efficient and effective movement of goods, services, and information. They use techniques such as just-in-time inventory management, demand forecasting, and transportation optimization to reduce costs and improve delivery times.

Key Activities:

- Analyzing supply chain data to identify trends and opportunities for improvement

- Developing and implementing supply chain optimization strategies

- Collaborating with suppliers and contractors to ensure smooth delivery of goods and services

- Managing inventory levels and ensuring just-in-time delivery

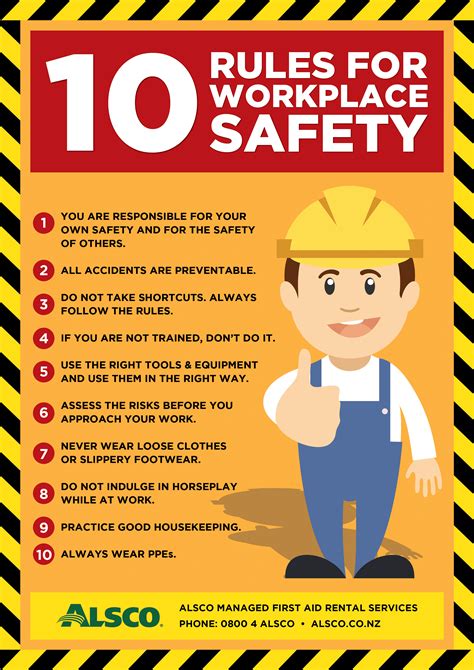

Ensuring Workplace Safety and Health

Industrial engineers are responsible for ensuring workplace safety and health by identifying and mitigating hazards, developing safety protocols, and training employees on safety procedures. They use techniques such as hazard analysis, risk assessment, and ergonomic design to create a safe and healthy work environment.

Key Activities:

- Conducting workplace safety audits to identify hazards and areas for improvement

- Developing and implementing safety protocols and procedures

- Collaborating with employees and management to ensure safety standards are met

- Analyzing data to identify trends and opportunities for improvement

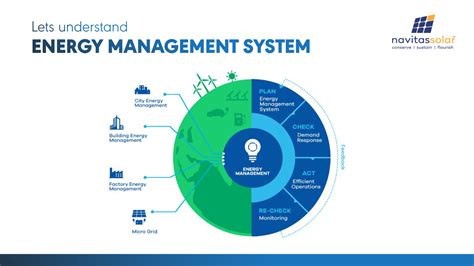

Managing and Reducing Energy Consumption

Industrial engineers are responsible for managing and reducing energy consumption by identifying opportunities for energy efficiency, developing energy-saving strategies, and implementing energy-efficient technologies. They use techniques such as energy auditing, energy modeling, and energy-efficient design to reduce energy consumption and costs.

Key Activities:

- Conducting energy audits to identify opportunities for energy efficiency

- Developing and implementing energy-saving strategies

- Collaborating with employees and management to ensure energy standards are met

- Analyzing data to identify trends and opportunities for improvement

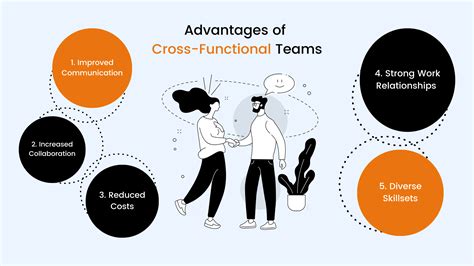

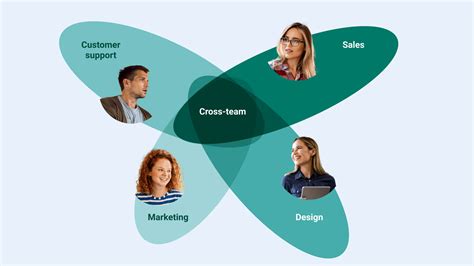

Collaborating with Cross-Functional Teams

Industrial engineers are responsible for collaborating with cross-functional teams, including production, quality, maintenance, and management, to ensure successful implementation of new systems and processes. They use techniques such as communication planning, stakeholder analysis, and conflict resolution to ensure effective collaboration.

Key Activities:

- Developing communication plans to ensure effective collaboration

- Conducting stakeholder analysis to identify key stakeholders and their needs

- Collaborating with cross-functional teams to ensure successful implementation

- Analyzing data to identify trends and opportunities for improvement

Staying Up-to-Date with Industry Trends and Developments

Industrial engineers are responsible for staying up-to-date with industry trends and developments by attending conferences, reading industry publications, and participating in online forums. They use techniques such as benchmarking, best practices analysis, and technology scanning to identify opportunities for improvement.

Key Activities:

- Attending conferences and industry events to stay up-to-date with industry trends

- Reading industry publications and online forums to stay informed

- Conducting benchmarking and best practices analysis to identify opportunities for improvement

- Analyzing data to identify trends and opportunities for improvement

Industrial Engineering Image Gallery

What is industrial engineering?

+Industrial engineering is a branch of engineering that deals with the design, improvement, and installation of systems, processes, and facilities to reduce costs, increase efficiency, and enhance the quality of products and services.

What are the key responsibilities of industrial engineers?

+Industrial engineers are responsible for designing and implementing efficient systems, improving quality and reducing waste, managing supply chains and logistics, ensuring workplace safety and health, managing and reducing energy consumption, collaborating with cross-functional teams, and staying up-to-date with industry trends and developments.

What skills do industrial engineers need to possess?

+Industrial engineers need to possess skills such as analytical and problem-solving skills, communication and collaboration skills, technical skills, and business acumen.

What is the role of industrial engineers in quality control?

+Industrial engineers play a crucial role in quality control by identifying and eliminating defects, variations, and inefficiencies in products and services. They use techniques such as Six Sigma, lean manufacturing, and total quality management to ensure quality standards are met.

How do industrial engineers contribute to workplace safety and health?

+Industrial engineers contribute to workplace safety and health by identifying and mitigating hazards, developing safety protocols, and training employees on safety procedures. They use techniques such as hazard analysis, risk assessment, and ergonomic design to create a safe and healthy work environment.

We hope this article has provided valuable insights into the key responsibilities of industrial engineers. If you have any questions or comments, please feel free to ask. Share this article with others who may be interested in learning more about industrial engineering.