Intro

Unlock the secrets of the SR-71 Blackbirds extraordinary quartz windows. Discover the 5 key factors behind their remarkable durability and ability to withstand extreme temperatures. Learn about the aircrafts thermal management, quartz glass properties, and the innovative manufacturing processes that made these windows a game-changer in aerospace engineering.

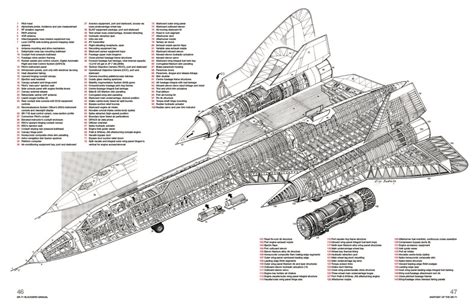

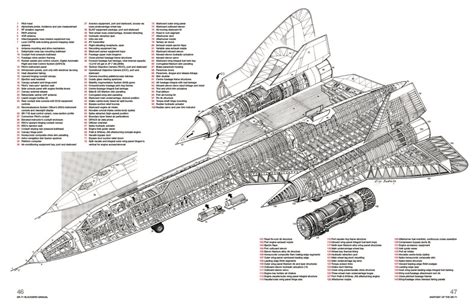

The SR-71 Blackbird, a supersonic reconnaissance plane developed by Lockheed Skunk Works, has been a topic of fascination for many years. One of the most intriguing aspects of this aircraft is its unique quartz windows. These windows played a crucial role in the SR-71's ability to gather intelligence while flying at incredibly high speeds. In this article, we will delve into the secrets of the SR-71's quartz windows and explore their design, functionality, and significance.

Secret 1: Quartz Glass vs. Traditional Glass

The SR-71's quartz windows were made from a specialized type of glass called fused quartz or fused silica. This material was chosen for its unique properties, which made it ideal for the SR-71's high-speed and high-altitude flights. Unlike traditional glass, quartz glass has a much lower coefficient of thermal expansion, which means it expands and contracts less when exposed to extreme temperature changes. This property was crucial for the SR-71, as it ensured that the windows would not shatter or become misshapen during flight.

Benefits of Quartz Glass

Quartz glass offered several benefits over traditional glass, including:

- Higher melting point: Quartz glass has a melting point of around 2,000°F (1,093°C), which made it perfect for the SR-71's high-speed flights.

- Lower thermal expansion: Quartz glass expands and contracts less than traditional glass, making it less prone to thermal shock.

- Higher optical clarity: Quartz glass has a higher optical clarity than traditional glass, which made it ideal for the SR-71's reconnaissance mission.

Secret 2: Window Design and Construction

The SR-71's quartz windows were designed and constructed to withstand the extreme conditions of high-speed flight. The windows were made up of multiple layers of quartz glass, which were carefully assembled to provide maximum strength and optical clarity. The windows were also designed to be extremely thin, with some areas as thin as 0.25 inches (6.35 mm). This thinness helped to reduce the weight of the aircraft and minimize the effects of thermal expansion.

Window Construction Process

The construction process of the SR-71's quartz windows was a complex and time-consuming process. The process involved:

- Cutting and polishing the quartz glass to precise dimensions

- Assembling the multiple layers of quartz glass

- Bonding the layers together using a specialized adhesive

- Testing the windows for optical clarity and strength

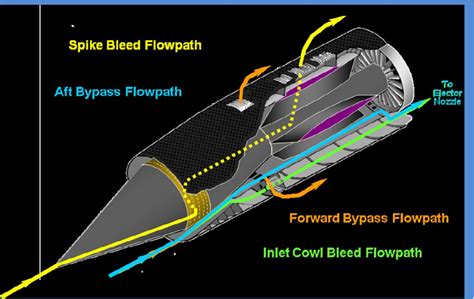

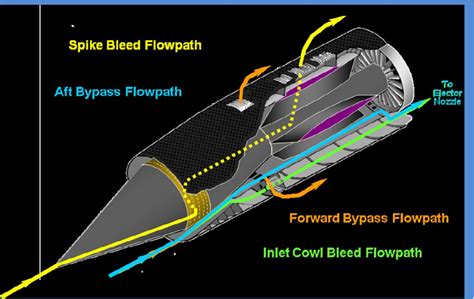

Secret 3: Cooling System

The SR-71's quartz windows were also equipped with a sophisticated cooling system, which helped to regulate the temperature of the windows during flight. The cooling system used a combination of air and fuel to cool the windows, which helped to prevent them from overheating or becoming misshapen.

Benefits of the Cooling System

The cooling system offered several benefits, including:

- Temperature regulation: The cooling system helped to regulate the temperature of the windows, which prevented them from overheating or becoming misshapen.

- Reduced thermal stress: The cooling system reduced the thermal stress on the windows, which helped to prolong their lifespan.

- Improved optical clarity: The cooling system helped to maintain the optical clarity of the windows, which was essential for the SR-71's reconnaissance mission.

Secret 4: Radar Absorbent Material

The SR-71's quartz windows were also coated with a radar absorbent material (RAM), which helped to reduce the aircraft's radar cross-section. The RAM was applied to the windows using a specialized process, which involved spraying a layer of RAM onto the surface of the glass.

Benefits of RAM

The RAM offered several benefits, including:

- Reduced radar cross-section: The RAM helped to reduce the SR-71's radar cross-section, making it more difficult to detect.

- Improved stealth: The RAM helped to improve the SR-71's stealth capabilities, making it a more effective reconnaissance platform.

Secret 5: Legacy of the SR-71's Quartz Windows

The SR-71's quartz windows have had a lasting impact on the development of modern aircraft. The technology used to create the SR-71's quartz windows has been adapted for use in a variety of applications, including commercial aviation and space exploration.

Legacy of the SR-71

The SR-71's quartz windows have left a lasting legacy in the world of aviation and aerospace. The technology used to create the windows has been improved upon and adapted for use in a variety of applications, including:

- Commercial aviation: The technology used to create the SR-71's quartz windows has been adapted for use in commercial aviation, where it is used to create high-strength, lightweight windows for aircraft.

- Space exploration: The technology used to create the SR-71's quartz windows has been adapted for use in space exploration, where it is used to create high-strength, lightweight windows for spacecraft.

SR-71 Quartz Windows Image Gallery

What were the SR-71's quartz windows made of?

+The SR-71's quartz windows were made from a specialized type of glass called fused quartz or fused silica.

Why were the SR-71's quartz windows so important?

+The SR-71's quartz windows were crucial for the aircraft's reconnaissance mission, as they provided a clear view of the surroundings and helped to gather intelligence.

What was the cooling system used for the SR-71's quartz windows?

+The cooling system used a combination of air and fuel to cool the windows, which helped to regulate the temperature and prevent overheating.

We hope you enjoyed this article about the SR-71's quartz windows. These windows played a crucial role in the aircraft's reconnaissance mission, and their design and construction are a testament to the innovative spirit of the engineers who worked on the SR-71 project.